- Low odor and low VOC, ensuring good in-car air quality.

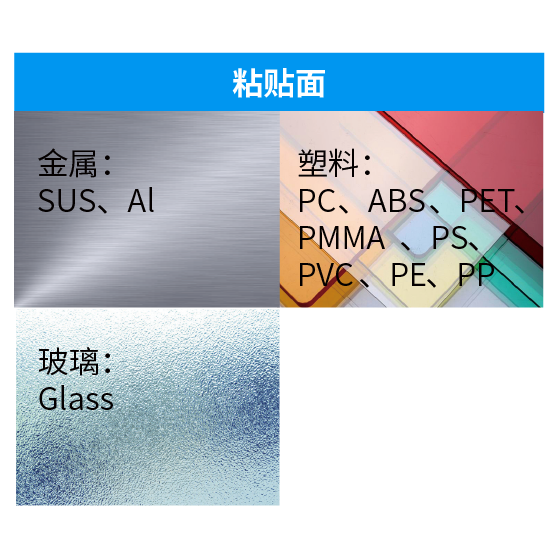

- Excellent adhesion to various materials (foam, plastics, etc.).

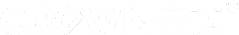

Automotive Industry

Crown provides high-performance, environmentally friendly bonding solutions

for automotive exterior parts, interior parts, displays, and other scenarios,

helping the automotive industry achieve extraordinary designs.

for automotive exterior parts, interior parts, displays, and other scenarios,

helping the automotive industry achieve extraordinary designs.

Discover Automotive Bonding Solutions

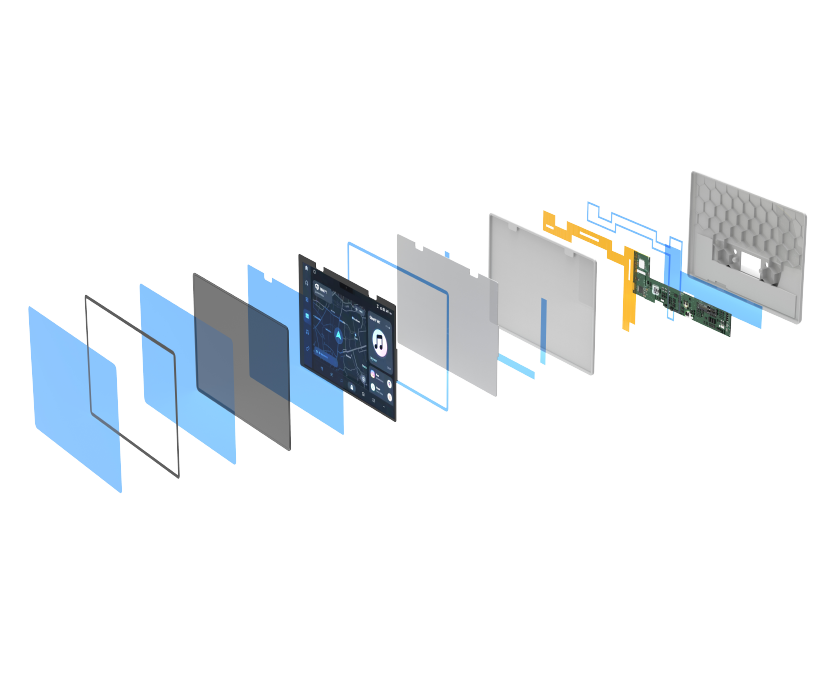

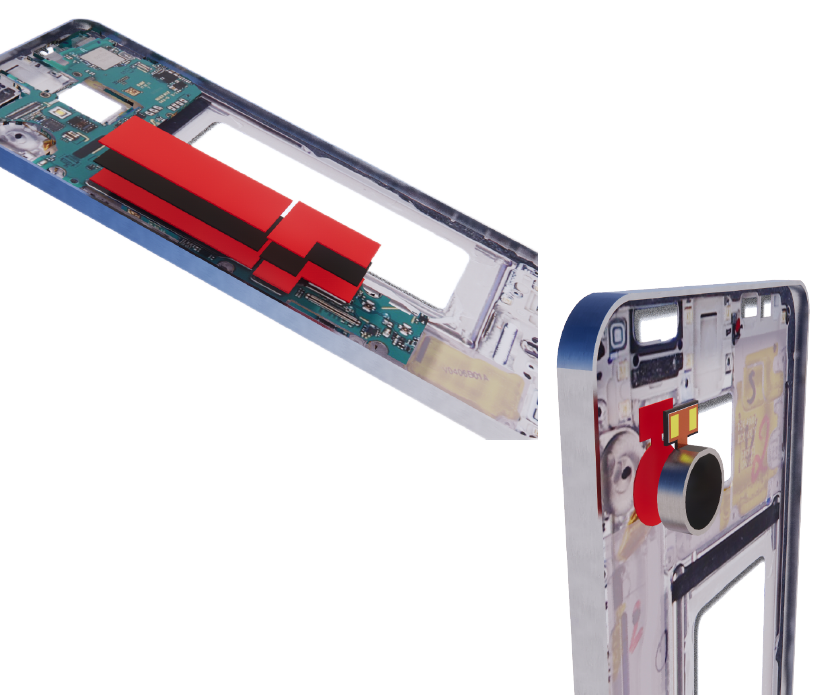

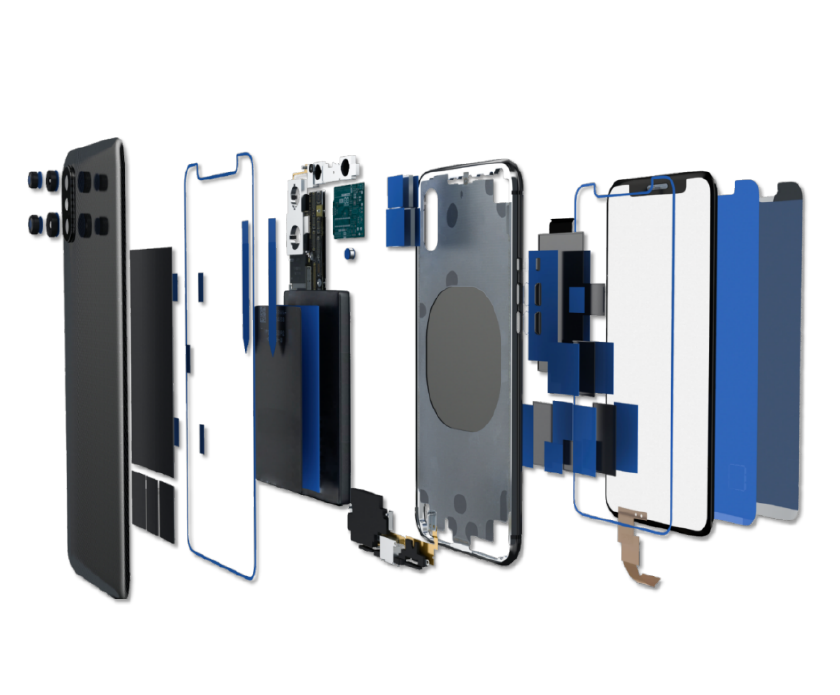

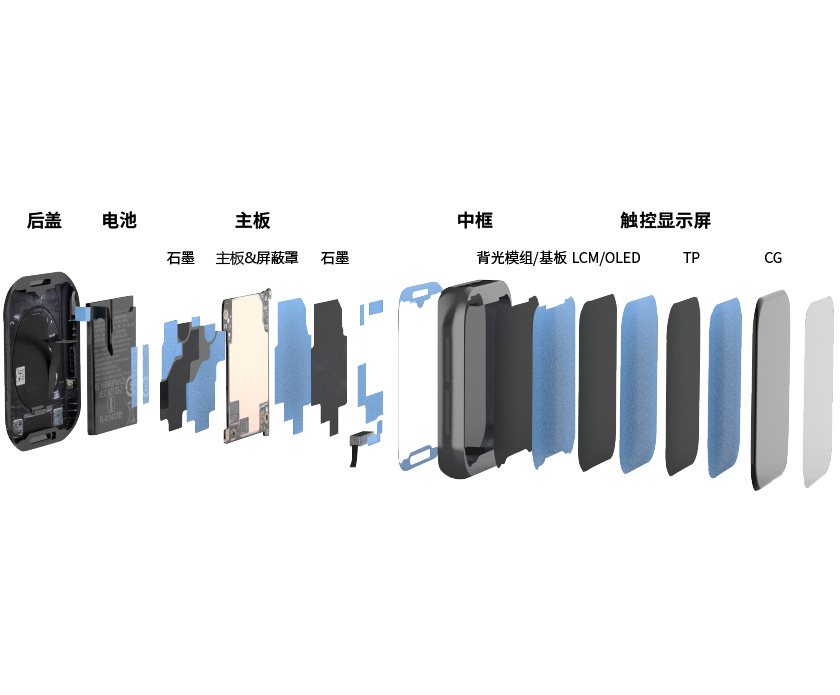

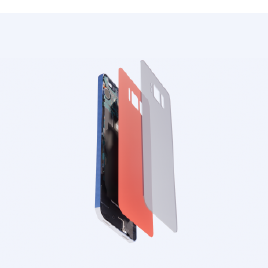

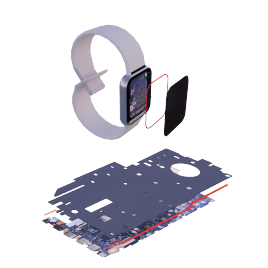

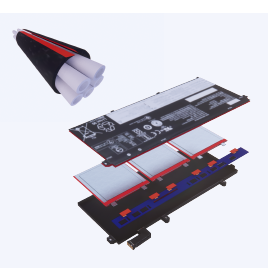

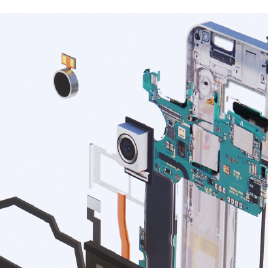

Consumer Electronics

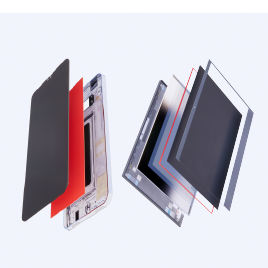

Crown focuses on consumer electronic devices such as smartphones, computers, and tablets,

committed to delivering stable and versatile bonding solutions to support the smart upgrade

of the consumer electronics industry.

committed to delivering stable and versatile bonding solutions to support the smart upgrade

of the consumer electronics industry.

Discover Consumer Electronics Bonding Solutions

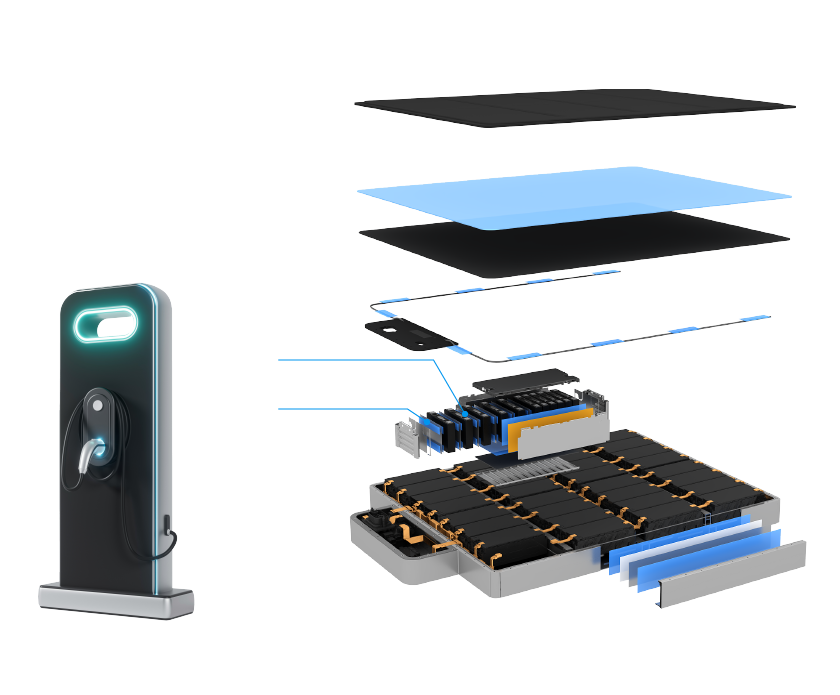

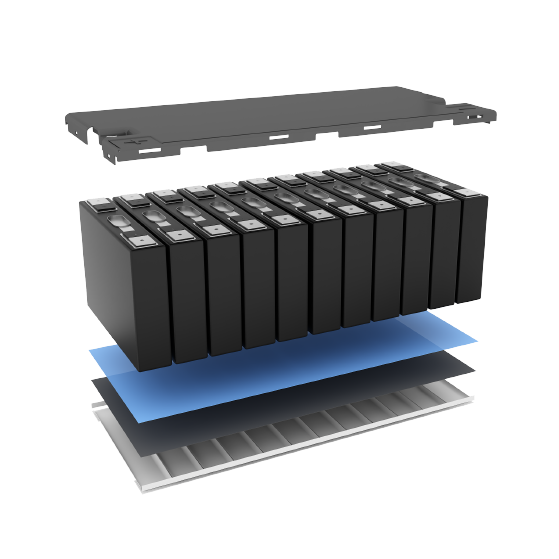

Green Energy

Crown is committed to driving green transformation, providing users in

the green energy industry with high-safety, high-reliability bonding solutions.

the green energy industry with high-safety, high-reliability bonding solutions.

Discover Green Energy Bonding Solutions

Home Appliances

Providing high-standard, all-encompassing bonding solutions.

Discover Home Appliances Bonding Solutions

Internet of Things (IoT)

Crown provides reliable bonding solutions for IoT devices, collaborating with

industry partners in the Internet of Everything to build a smarter world.

industry partners in the Internet of Everything to build a smarter world.

Discover Internet of Things Bonding Solutions

Home Living

Crown offers diversified and multifunctional bonding solutions for

various home living scenarios, including home decoration and

windproof insulation, helping to create a high-quality lifestyle.

various home living scenarios, including home decoration and

windproof insulation, helping to create a high-quality lifestyle.

Discover Home Living Bonding Solutions

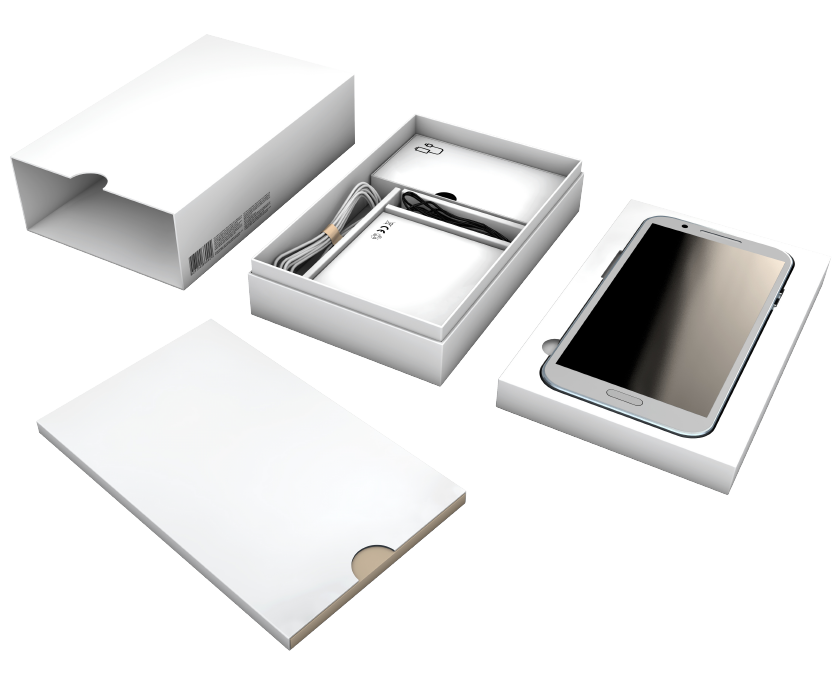

Innovative Packaging

Crown is committed to promoting green, low-carbon development,

providing industry users with eco-friendly and durable bonding

solutions to help build a sustainable and resilient industrial ecosystem.

providing industry users with eco-friendly and durable bonding

solutions to help build a sustainable and resilient industrial ecosystem.

Discover Innovative Packaging Bonding Solutions

Transportation

Crown provides the transportation industry with strong and durable bonding solutions,

helping industry users innovate and upgrade for high-quality development.

helping industry users innovate and upgrade for high-quality development.

Discover Transportation Bonding Solutions

Industrial Manufacturing

Crown provides the industrial manufacturing sector with efficient bonding solutions, enhancing

the operational efficiency of complex manufacturing processes and supporting smooth project delivery.

the operational efficiency of complex manufacturing processes and supporting smooth project delivery.

Discover Industrial Manufacturing Bonding Solutions

Other

Crown focuses on a wide range of industries, expanding limitless possibilities

through diversified products and functions, and helping industry users achieve advanced growth.

through diversified products and functions, and helping industry users achieve advanced growth.

Discover Other Industry Bonding Solutions

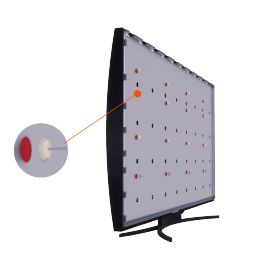

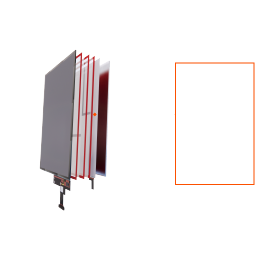

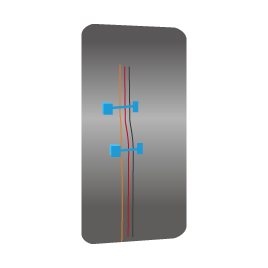

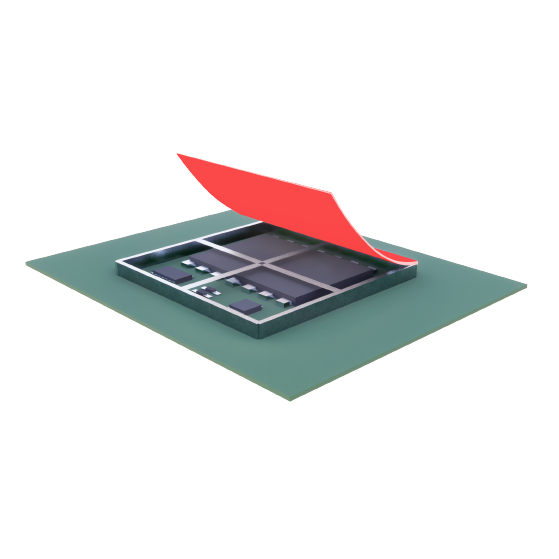

Backlight Panel Support Frame Fixation

|

| Series | Thickness(μm) | Color | Adhesive | Carrier |

| EPT | 400/640/1100 | White | Acrylic | Acrylic Foam |

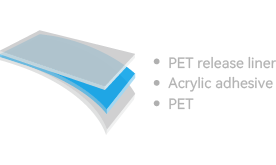

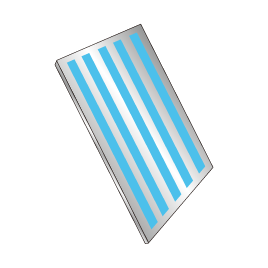

Fixation of Backlight Functional Films for LCD Screens

Product Features

|

| Series | Thickness(μm) | Color | Adhesive | Carrier |

| High-performance PET Tape | 50/100 | Transparent | Acrylic | PET |

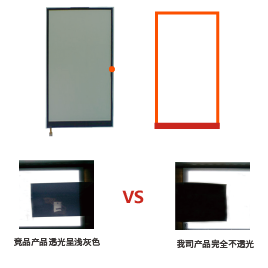

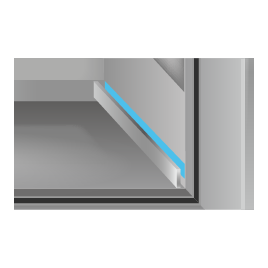

LCD Screen Light Blocking Solutions

ChatGPT 说: |

| Series | Thickness(μm) | Color | Adhesive | Carrier |

| (Double-Sided Black) Light Shielding Tape | 50/60 | Black | Acrylic | PET |

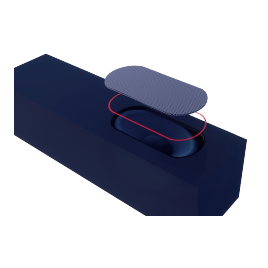

Speaker Mesh Fixation

|

| Series | Thickness(μm) | Color | Adhesive | Carrier |

| High performance Tissue Tape | 100/150/200 | Black | Acrylic | Tissue |

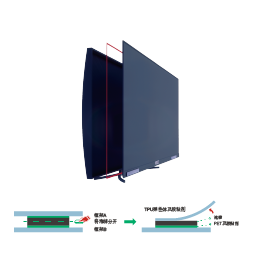

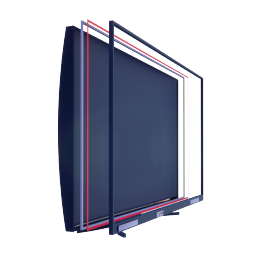

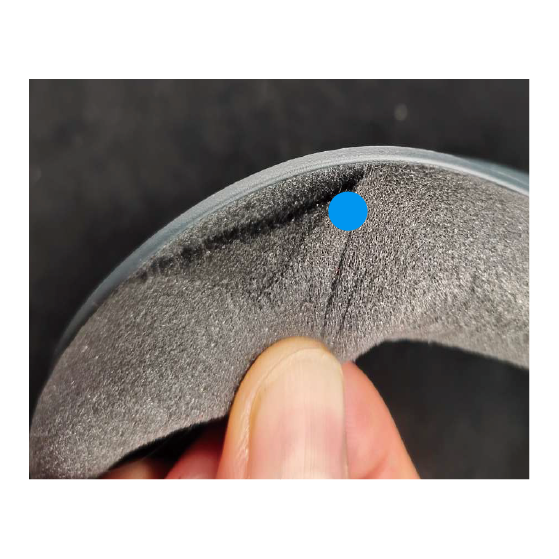

Bezel-Less Display Screen Sealing

|

| Series | Thickness(μm) | Color | Adhesive | Carrier |

| Removable PU Foam Tape | 850 | Black | Acrylic | PU Foam Composite Carrier |

Base Foot Pad Adhesive Fixation

|

| Series | Thickness(μm) | Color | Adhesive | Carrier |

| High performance Tissue Tape | 120/140/150/160 | Translucent | Acrylic | Tissue |

| High-performance Adhesive Transfer Tape | 60/130 | Transparent | Acrylic | - |

Cushioning Silicone Strip Fixation

|

| Series | Thickness(μm) | Color | Adhesive | Carrier |

| AB Differential Tape | 50/100/140 | Transparent | Side A: Acrylic; Side B: Silicone | PET |

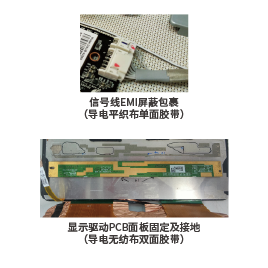

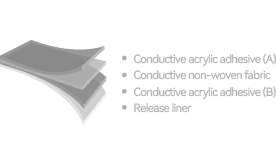

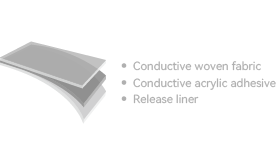

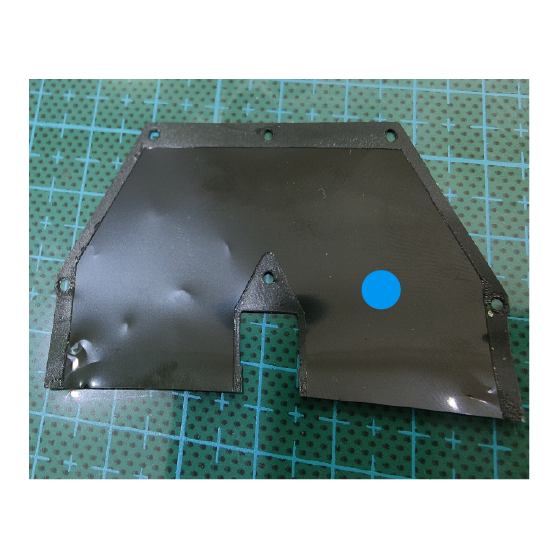

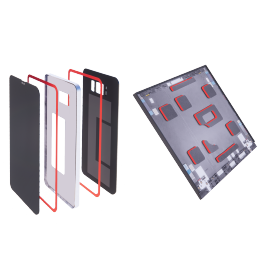

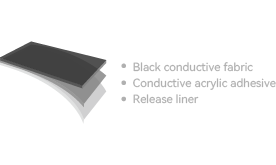

Electromagnetic Shielding Wrapping / Component EMI Shielding and Grounding

|

| Series | Thickness(μm) | Adhesive | Carrier |

| Conductive Fabric Tape(Single-Sided) | 70-180 | Acrylic | Conductive Plain Weave Fabric |

| Conductive Fabric Tape(Double-Sided) | 50-150 | Acrylic | Conductive Nonwoven Fabric |

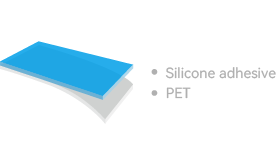

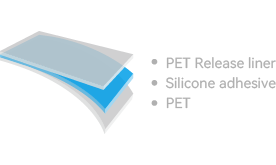

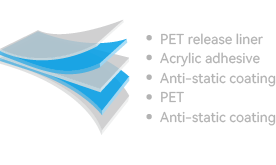

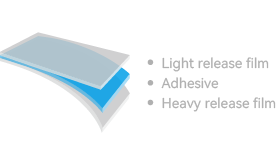

Shipping Protection

Product Features

|

| Series | Thickness(μm) | Color | Adhesive | Carrier | Notes |

| Silicone Double-Layer Protective Film | 60/80 | Transparent | Silicone | PET | Suitable for Screen Shipping Protection |

| Silicone Single-Layer Protective Film | 38/50/75 | Transparent | Silicone | PET | Suitable for Shell Shipping Protection |

Nameplate and Label Adhesive Fixation

|

| Series | Thickness(μm) | Color | Adhesive | Carrier |

| High performance Tissue Tape | 120/140/150/160 | Translucent | Acrylic | Tissue |

| PE Foam Tape | 500/600 | Black/White | Acrylic | PE Foam |

Window Frame Fixation

|

| Series | Thickness(μm) | Adhesive | Carrier |

| PE Foam Tape | 100-500 | Acrylic | PE Foam |

| PE Foam Tape with Reinforced Film | 200-300 | Acrylic | PE Foam with Reinforced Film |

| Acrylic Foam Tape with Reinforced Film | 300 | Acrylic | Acrylic Foam with Reinforced Film |

| Heat-Activated Low-Tack Foam Tape | 250 | Acrylic | PE Foam |

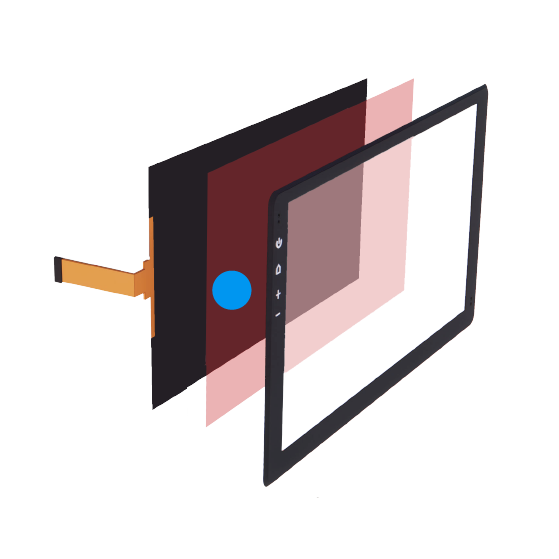

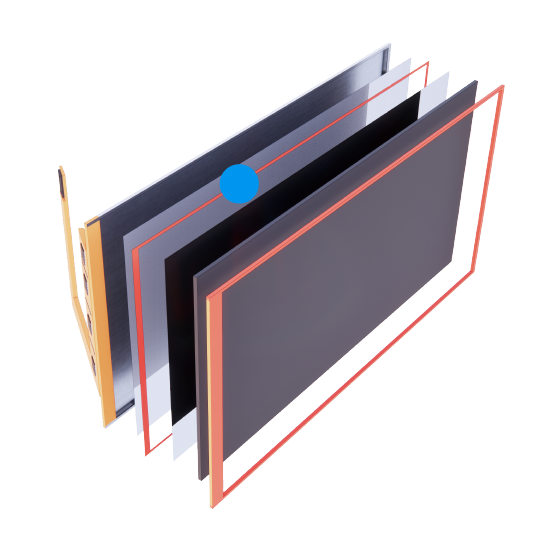

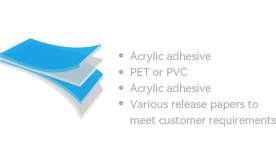

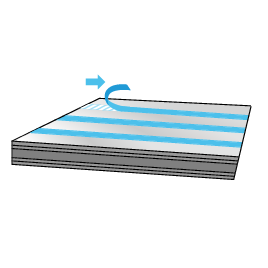

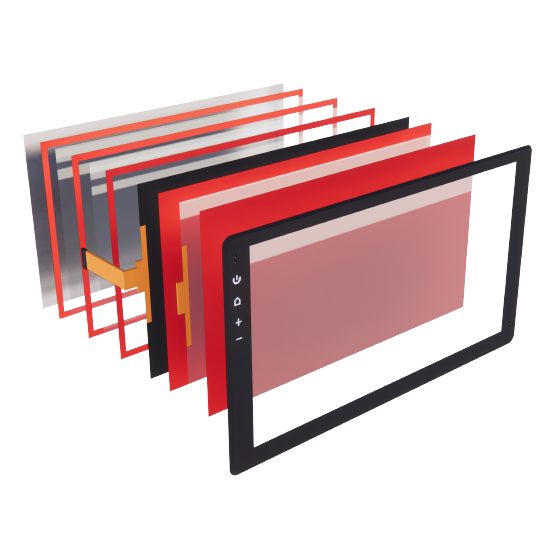

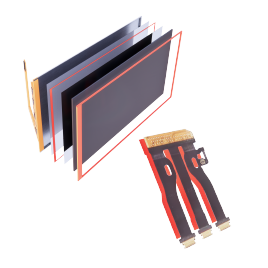

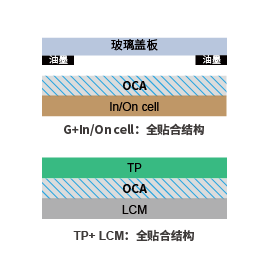

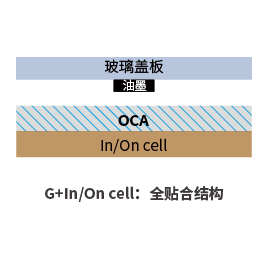

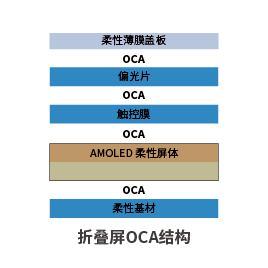

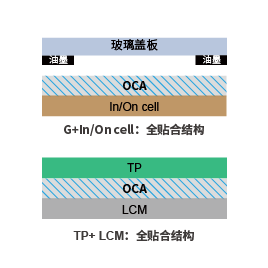

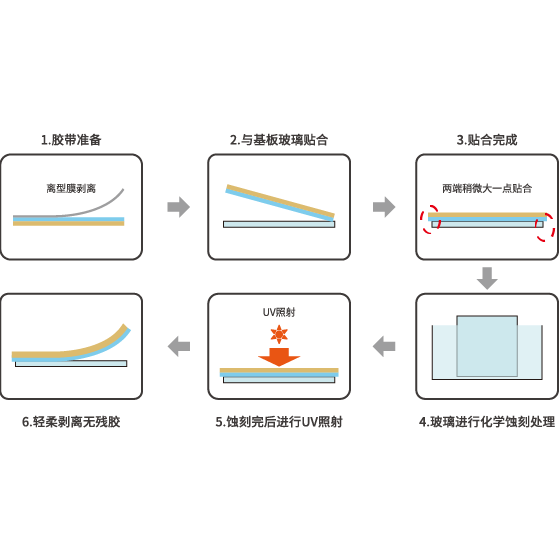

Display Panel Bonding – OCA Solutions for Functional Films

|

| Series | Thickness(μm) | Color | Adhesive | Application |

| OCA for Functional Films | 60/80 | Transparent | Acrylic | ITO Bonding, Polarizer Bonding, and Bonding of Other Optical Components |

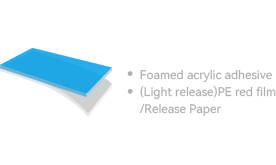

Display Panel Bonding – Full Lamination OCA Solutions

|

| Series | Thickness(μm) | Adhesive | Adhesive | Application |

| Full Lamination OCA | 100/125/150/175 | Softness | Acrylic | Suitable for bonding G+G, TP+LCM, CG+ In-cell, CG+ On-cell, and other module bonding applications |

Decorative Component Bonding and Fixation

|

| Series | Thickness(μm) | Color | Adhesive | Carrier |

| PE Foam Tape | 200-3000 | Black/White | Acrylic | PE Foam |

| EPT | 200/400/640/800/1000 | Black/White/Transparent | Acrylic | Acrylic Foam |

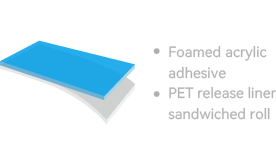

Secure Transport Fixation

|

| Series | Thickness(μm) | Color | Adhesive | Carrier |

| Refrigerator Tape | 60 | Blue | Acrylic | PET |

Evaporator Bonding

|

| Series | Thickness(μm) | Color | Adhesive | Carrier |

| High performance Tissue Tape | 120/140/150/160 | Translucent | Acrylic | Tissue |

Cushioning Adhesive Layer

|

| Series | Thickness(μm) | Color | Adhesive | Carrier |

| High Cleanliness Ultra-Thin High Adhesion Tape | 125/225 | Transparent | Acrylic | PET |

Laminating Adhesive Layer

|

| Series | Thickness(μm) | Color | Adhesive | Carrier |

| High Cleanliness Ultra-Thin High Adhesion Tape | 125/225 | Transparent | Acrylic | PET |

Bottom Adhesive Layer

|

| Series | Thickness(μm) | Color | Adhesive | Carrier |

| High performance Tissue Tape | 120/140/150/160 | Translucent | Acrylic | Tissue |

| High-Performance LSE Tape | 170/150 | Transparent | Acrylic | PET |

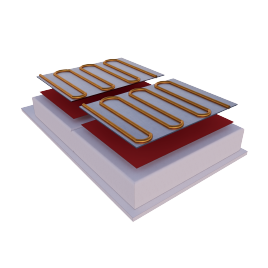

Heating Plate Bonding

|

| Series | Thickness(μm) | Color | Adhesive | Carrier |

| High performance Tissue Tape | 160 | Translucent | Acrylic | Tissue |

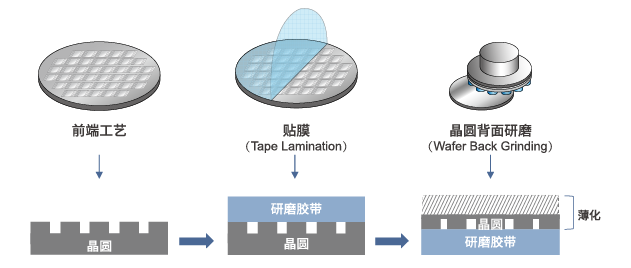

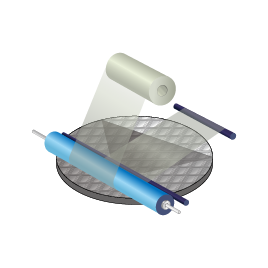

晶圆研磨-晶圆研磨胶带

加工难点

| 产品特性

|

| 产品 | 型号 | 产品特征 | 制程条件推荐 | 锡球高度范围 | 基材材质 | 颜色 | 产品厚度 | UV前粘着力 (gf/in) | UV后粘着力 (gf/in) |

| UV减粘胶带 | UC1010 | 软胶,耐高温,填充性能好,微耐酸 | 晶圆表面研磨 | ≤20μm | PO | 浅蓝色 | 130μm | >300 | <20 |

| UV减粘胶带 | UC1020 | 硬胶,抗残胶性能好,耐酸 | 晶圆表面研磨 | ≤20μm | PO | 浅蓝色 | 130μm | >300 | <20 |

| UV减粘胶带 | UC1100 | 胶性稳定,填充性能好,不残胶 | 高锡球晶圆研磨 | 100-300μm | PET复合材料 | 透明 | 595μm | >100 | <20 |

| 非UV减粘胶带 | UN2008 | 胶性稳定,高精度,不残胶 | 一般晶圆研磨 | / | PVC | 蓝色 | 80μm | 70-130 | 70-130 |

晶圆研磨-撕膜胶带

加工难点

| 产品特性

|

| 产品 | 型号 | 产品特征 | 基材材质 | 颜色 | 产品厚度 | 应用温度(°C) | 粘着力 (gf/in) |

| 温控胶带 | TR4003 | 热熔型撕膜胶带 | PET | 乳白色 | 80μm | 100-230 | >2000 |

| 非UV减粘胶带 | UN4003 | 常规型撕膜胶带 | PET | 透明 | 80μm | 23±5 | >1000 |

| 非UV减粘胶带 | UN4004 | 常规型撕膜胶带 | PET | 透明 | 80μm | 23±5 | >1000 |

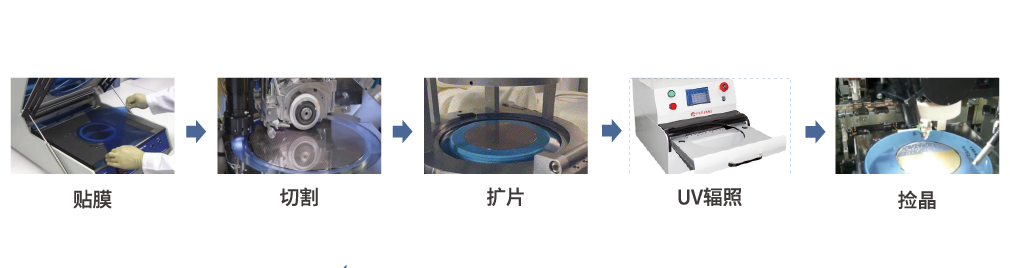

晶圆切割扩片-晶圆切割胶带

加工难点

| 产品特性

|

| 型号 | 产品特征 | 制程条件推荐 | 基材材质 | 颜色 | 产品厚度 | 减粘前粘着力 (gf/in) | 减粘后粘着力 (gf/in) | 备注 |

| UC2104 | 适合多种材质粘接,可扩膜,捡晶用 | 常规切割 | PO | 透明 | 90μm | ≥300 | ≤30 | UV减粘胶带 |

| UC2100 | 高粘性,延展性好,可捡晶 | 中小尺寸切割 | PO | 透明 | 90μm | ≥1000 | ≤30 | UV减粘胶带 |

| UC2073 | 稳定性佳,延展性好,可捡晶 | 中小尺寸切割 | PVC | 蓝色 | 80μm | ≥250 | ≤30 | UV减粘胶带 |

| UC2074 | 稳定性佳,延展性好,可捡晶 | 中小尺寸切割 | PVC | 透明 | 80μm | ≥150 | ≤30 | UV减粘胶带 |

| UN2008 | 稳定性佳,延展性好,可捡晶 | 中小尺寸切割 | PVC | 蓝色 | 80μm | 70-130 | 70-130 | 非UV胶带 |

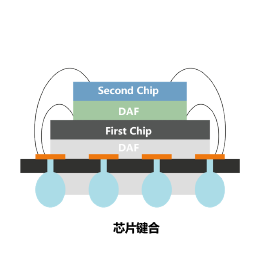

晶圆切割扩片-DAF膜

加工难点

| 产品特性

|

| 型号 | TMA-固化完成 CTE-Alpha 1 | TMA-固化完成 CTE-Alpha 2 | DMA-固化完成 Tg | DMA-固化完成 Modulus@50°C | DMA-固化完成 Modulus@250°C | 拉力-PCT PCT-96H (2atm) | Dk 1MHz | Df 1MHz |

| CB1001 | 50 ppm/°C | 90 ppm/°C | 180°C | 6300 MPa | 120 MPa | 36 kg/cm2 | 3.67 | 1 |

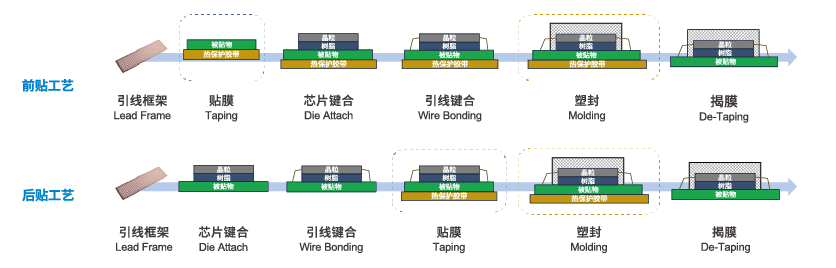

晶圆封装-热保护胶带

加工难点

| 产品特性

|

| 型号 | 制程条件推荐 | 基材材质 | 胶系 | 产品厚度 | 粘着力 (gf/in) | 耐温性能 | 备注 |

| TF3025S | 前贴 | PI | 硅胶 | 30μm | 50-100 | 260oC 3h | 高端制程使用 |

| TF3015S | 前贴 | PI | 硅胶 | 32μm | 150-300 | 260oC 1.5h | 通用类产品 |

| TF3020S-4 | 后贴 | PI | 硅胶 | 32μm | 50-150 | 220oC 3h | 低粘,高性价比之选 |

| TF3033S | 后贴 | PI | 硅胶 | 32μm | 300-500 | 220oC 3h | 高粘,高性价比之选 |

| TF2004 | 后贴 | PI | 丙烯酸胶 | 35μm | 50-150 | 180oC 3h | 非硅耐温 |

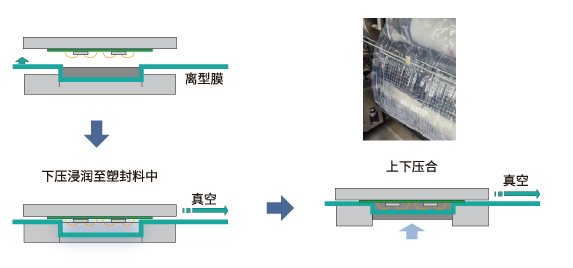

晶圆封装-注塑离型膜

加工难点

| 产品特性

|

| 型号 | 产品特征 | 耐温性能 | 基材材质 | 产品厚度 | 备注 |

| TF2002 | 单面哑光,Ra<0.5,阻胶性优良 | 180℃ 0.5H | PET | 77±3μm | 带胶 |

| TF4001 | 双面哑光,Ra<0.5 | 180℃ 0.5H | PET | 45-50μm | 不带胶 |

| TF4002 | 单面哑光,Ra<0.5 | 180℃ 0.5H | PET | 41-45μm | 不带胶 |

| NS2002 | 离型力300gf/in左右 | 180℃ 0.5H | PET | 41-45μm | 非硅离型膜 |

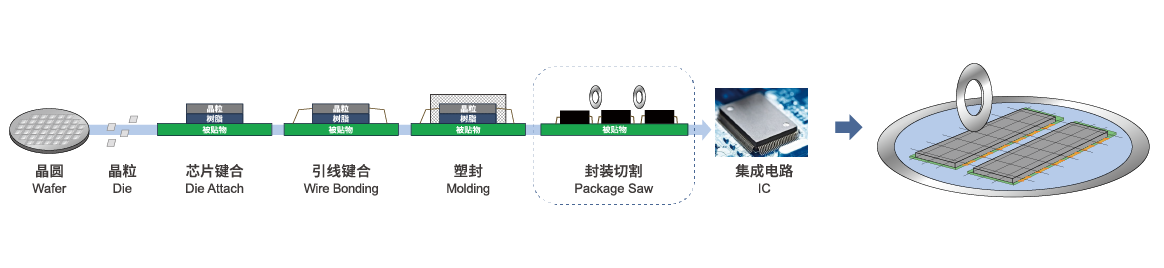

晶圆封装切割-封装切割胶带

加工难点

| 产品特性

|

| 型号 | 产品特征 | 制程条件推荐 | 基材材质 | 产品厚度 | UV前粘着力 (gf/in) | UV后粘着力 (gf/in) |

| UC2111-2 | 切割不飞片,无残胶,无膜丝 | 高台阶 | PO | 180μm | ≥2000 | ≤10 |

| UC2111 | 切割不飞片,无残胶,无膜丝 | 通用 | PO | 165μm | ≥2000 | ≤10 |

| UC2124 | 切割不飞片,无残胶,无膜丝 | 高翘曲 | PO | 180μm | ≥2000 | ≤20 |

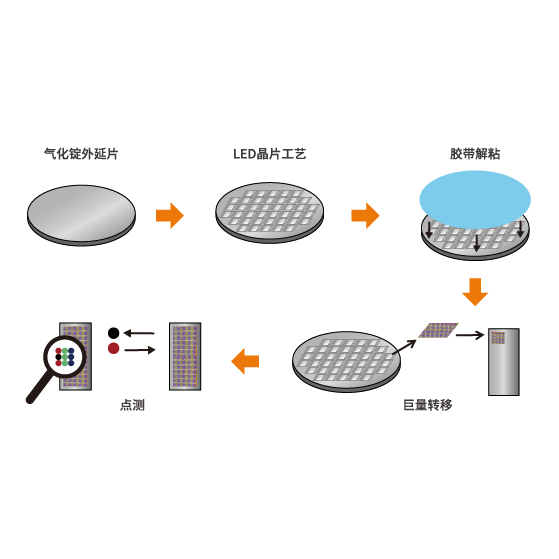

先进LED制程胶带

加工难点

| 产品特性

|

| 型号 | 特征 | 制程条件推荐 | 基材材质 | 颜色 | 产品厚度 (μm) | UV前粘着力 (gf/in) | UV后粘着力 (gf/in) |

| UC2080 | 高粘,适合多种材质粘接,可扩膜,捡晶用 | 一般LED | PET | 透明 | 125 | ≥2000 | ≤20 |

| UC2098 | 切割不飞片,适合多种材质,下料轻松 | Mini-LED | PO | 透明 | 115 | ≥1500 | <10 |

| UN2081 | 翻晶效果好,防穿刺性能好,置晶好 | 巨量转移 | PO | 蓝色 | 150 | ≥80 | ≥80 |

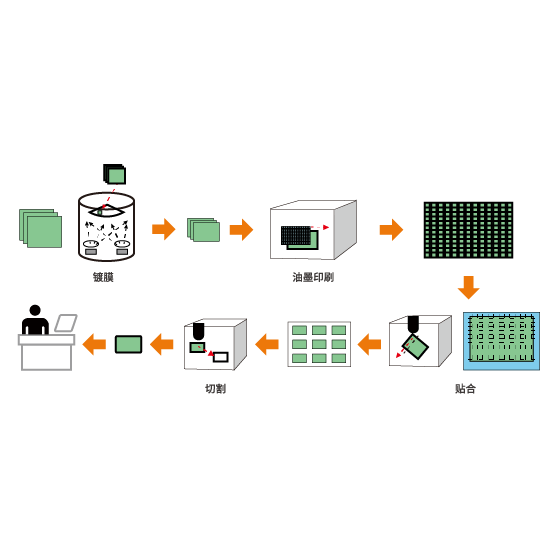

滤光片切割胶带

加工难点

| 产品特性

|

| 型号 | 特征 | 制程条件推荐 | 基材材质 | 产品厚度 (μm) | UV前粘着力 (gf/in) | UV后粘着力 (gf/in) |

| UC2001 | 通用 | 非丝印面贴合 | PO | 90 | ≥1000 | ≤20 |

| UC2035 | 无渗水,无残胶,无膜印 | 丝印面贴合 | PO | 90 | ≥1200 | ≤10 |

制程保护膜

加工难点

| 产品特性

|

| 型号 | 特征 | 制程条件推荐 | 基材材质 | 产品厚度 (μm) | UV前粘着力 (gf/in) | UV后粘着力 (gf/in) |

| UC2008 | 高耐酸 | 有高耐酸要求的应用 | PO | 165 | ≥1300 | <10 |

| UC2011 | 高耐酸 | 有高耐酸要求的应用 | PET | 65 | ≥1000 | <10 |

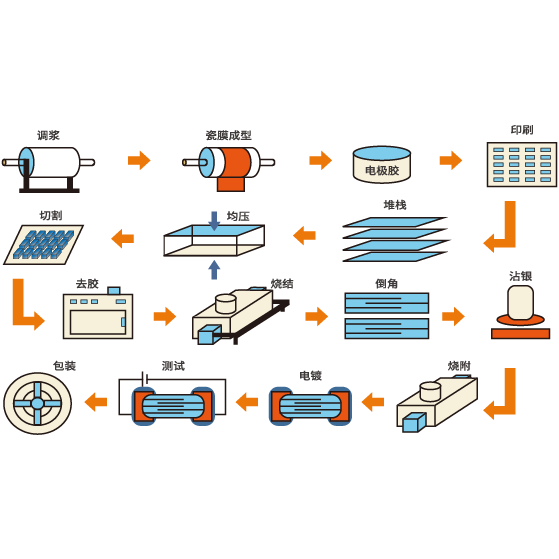

温控发泡减粘胶带

加工难点

| 产品特性

|

| 型号 | 特征 | 制程条件推荐 | 基材材质 | 产品厚度 (μm) | 解粘前粘着力 (gf/in) | 解粘后粘着力 (gf/in) | 解粘温度 |

| TR1001 | 常温可减粘,可复用 | MLCC切割 | PET | 140 | 100-500 | <1g | 10℃-30℃ |

| TR2004 | 可热水减粘 | 制程保护 | PET | 100 | ≥1500 | <1g | 90℃-100℃ |

| TR3002 | 不残胶,无位移 | MLCC切割 | PET | 160 | >1300 | <1g | 130℃-140℃ |

| TR4001 | 耐酸碱,高耐温性 | 封装 | PET | 110 | 200-500 | <1g | >190℃ |

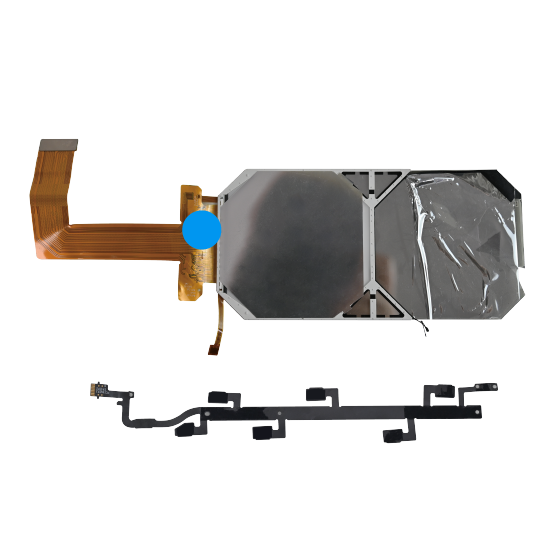

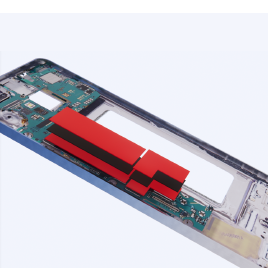

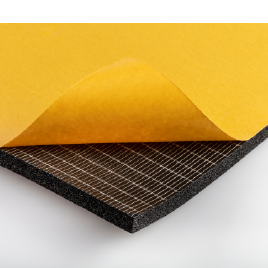

The graphite sheet is bonded and fixed

Product features

| Product advantages

|

| Product | Grade Name | Thickness(μm) | Carrier | Color | Adhesive | 180° SUSPeel Strength(N/cm) |

| High Cleanliness PET Double-Sided Tape | DT76xxB | 5-30 | PET | Black/Transparent/Black Translucent | Acrylic | 1.2-8 |

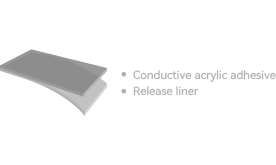

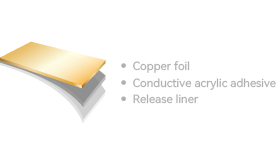

Conductive shielding

Product features

| Product advantages

|

| Product | Grade Name | Thickness(μm) | Carrier | Adhesive | 180° Peel Strength(N/25mm) | Z-Axis Vertical Resistance(Ω/inch²) |

| Conductive Adhesive Film | ED0xH | 10-100 | Adhesive Transfer | Conductive Acrylic | 7-19 | <0.03 |

| Conductive Nonwoven Fabric Tape | EMx301 | 20-100 | Conductive Nonwoven Fabric | Conductive Acrylic | 6-15 | <0.02 |

| Conductive Plain Weave Fabric Tape | EMx201 | 30-200 | Conductive Plain Weave Fabric | Conductive Acrylic | 10-18 | <0.05 |

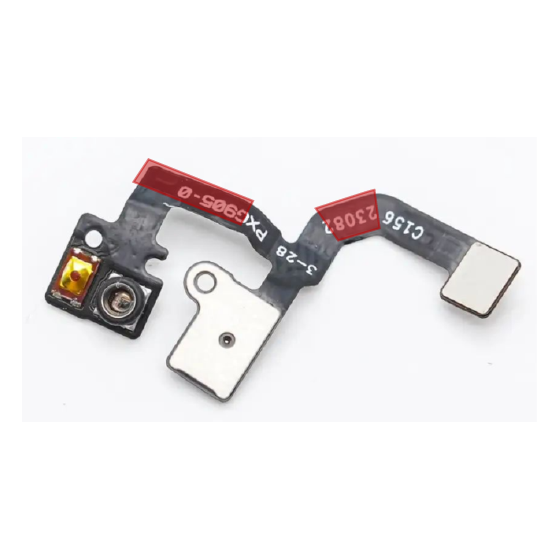

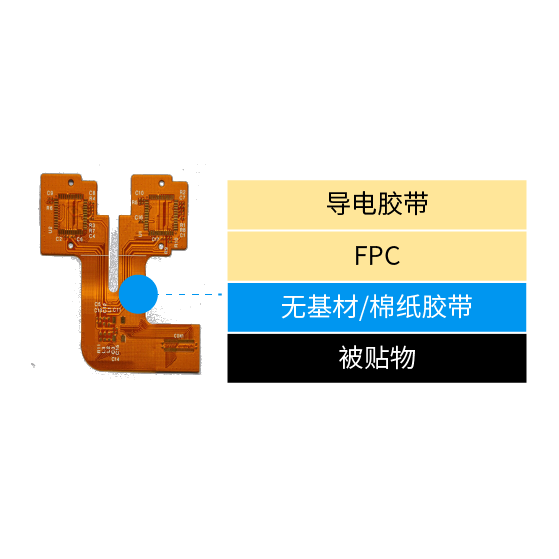

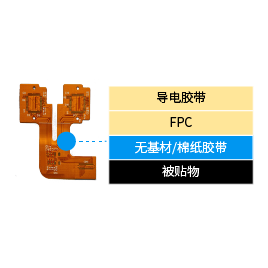

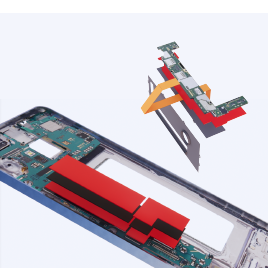

The FPC is bonded and fixed

Product features

| Product advantages

|

| Product | Grade Name | Thickness(μm) | Carrier | Adhesive | 180° SUSPeel Strength(N/cm) |

| High-performance PET Tape | P89721G/P89821G | 50/120 | PET | Acrylic | 4-8 |

| High-performance Adhesive Transfer Tape | N506/N513 | 60/130 | Adhesive Transfer | Acrylic | 5-7 |

The components are bonded and fixed

Product features

| Product advantages

|

| Product | Grade Name | Thickness(μm) | Carrier | Adhesive | 180° SUSPeel Strength(N/cm) |

| PET Double-Sided Tape | P89721G/P89821G | 50/120 | PET | Acrylic | 4-8 |

Optical Bonding for Screen Modules

Recommended Product

| Product Advantages

|

| Product | Grade Name | Thickness(μm) | Adhesive | Yellowness Indexb* | Haze | Transmittance(%) |

| OCA | CR-934xN | 100-200 | Acrylic | <0.4 | <0.4 | >90 |

Screen Module Frame Bonding

Product Features

| Product Advantages

|

| Product | Grade Name | Thickness(μm) | Carrier | Adhesive | 180° SUSPeel Strength(N/cm) |

| Removable PU Foam Tape | CRU-DM3407BB | 850 | PU Foam Composite Carrier | Acrylic | >6 |

| EPTAcrylic Foam Tape | A7xxBT/BR | 200-1100 | Acrylic Closed-Cell Foam | Acrylic | 25-50 |

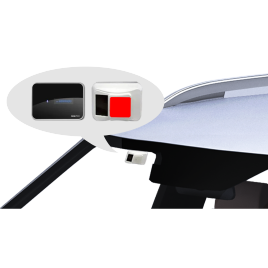

Lens Fixation

Product Features

| Product Advantage

|

| Product | Grade Name | Thickness(μm) | Carrier | Adhesive | 180° SUSPeel Strength(N/cm) | Static Shear Holding Power(min) |

| EPTAcrylic Foam Tape | A7xxBT/BR | 200-1100 | Acrylic Closed-Cell Foam | Acrylic | 25-50 | >1440 |

| PET Double-Sided Tape | P89721G/P89821G | 50/120 | PET | Acrylic | 45390 | >1440 |

Structural Cushioning Bonding

Product Features

| Product Advantages

|

| Product | Grade Name | Thickness(μm) | Carrier | Adhesive | 180° SUSPeel Strength(N/cm) | Static Shear Holding Power(min) |

| EPT | A7xxBSeries | 200-1100 | Acrylic Closed-Cell Foam | Acrylic | 25-50 | >1440 |

| PE Foam Tape | DP02xxGSeries | 100-500 | PE Foam | Acrylic | 16-26 | >1440 |

Fabric to Plastic Bonding

Product Features

| Product Advantages

|

| Product | Grade Name | Thickness(μm) | Adhesive | 180° SUSPeel Strength(N/cm) | Static Shear Holding Power(min) |

| Adhesive Transfer Double-Sided Tape | N506N/N513H | 60/130 | Acrylic | ≥5 | >10000 |

Rubber Pad Bonding and Fixation for Handle Buttons

Product Features

| Product Advantages

|

| Product | Grade Name | Thickness(μm) | Carrier | Adhesive | 180° Peel Strength(N/cm) |

| AB Double-Sided Tape | ABxxTF | 50-140 | PET | Silicone/Acrylic | 4.5-16.6 SUS 5-8.3 Si |

Structural Cushioning

Product Features

| Product Advantages

|

| Product | Grade Name | Thickness(μm) | Carrier | Adhesive | 180° SUSPeel Strength(N/cm) | Static Shear Holding Power(min) |

| PU Foam Single-Sided Tape | SUxxB | 150-2000 | PU Foam | Acrylic | 3-10 | >1440 |

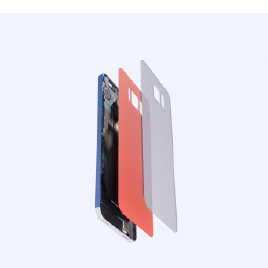

Cover Protection

Product Features

| Product Advantages

|

| Product | Grade Name | Thickness(μm) | Carrier | Adhesive | 180° SUSPeel Strength(N/cm) |

| High Cleanliness Ultra-Thin High Adhesion PET Single-Sided Adhesive | STxx | 5-30 | PET | Acrylic | 1.2-8 |

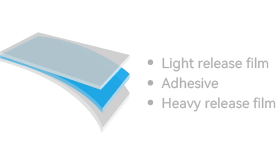

Packing

Product features

| Product advantages

|

| Product | Grade Name | Thickness(μm) | Carrier | Adhesive | 180° Peel Strength(N/cm) | Static Shear Holding Power(min) |

| AB Differential Tape | AB1203TF/AB20115T | 57/70 | PET | Silicone/Acrylic | 2-4 Si >6 SUS | ≥10000 |

| Tissue Tape | DS5xx Series | 100-160 | Tissue | Acrylic | 4-10.4SUS | ≥1440 |

Shipment protection

Product features

| Product advantages

|

| Product | Grade Name | Thickness(μm) | Carrier | Adhesive | 180° SUSPeel Strength(N/cm) | Anti-Static Value (Film Resistance & Adhesive Resistance) Ω |

| Protective Film | RW9213 | 50 | PET | Anti-static Acrylic | 45299 | 10⁶⁻¹¹ |

FPC Bonding and Fixation

|

| Product | Grade Name | Thickness(μm) | Carrier | Adhesive | 20min 180°SUSPeel Strength(N/cm) |

| High-Performance PET Double-Sided Tape | P89721G/P89821G | 50/100 | PET | Acrylic | ≥4.5/≥8 |

| High-performance Adhesive Transfer Tape | N506/N513 | 60/130 | None | Acrylic | ≥5.2/≥7.5 |

| High-Performance LSE Double-Sided Tape | P8929LE/P8967LEAH | 150/170 | PET | Acrylic | 7/7.2 |

Removable Packaging for Electronic Products

|

| Product | Thickness(μm) | Colour | Adhesive | Carrier |

| EPT | 400/640/1100 | White | Acrylic | Acrylic Foam |

Battery Cushioning and Fixation

|

| Product | Grade Name | Thickness(μm) | Carrier | Adhesive | 180°SUSPeel Strength(N/cm) |

| High-Performance PET Tape | P89722G/P89822G | 50/100 | PET | Acrylic | ≥5.5/≥10(20min) |

| Acrylic Foam TapeEPT | H0008/H0009 | 50/130 | Acrylic Foam | Acrylic | 10/12.8(72h) |

| Pull-Off Tape | CRN-DPxxxxL | 50~1000 | None | Rubber | >4~>14(20min) |

Electronic Product Packaging Materials

|

| Product | Grade Name | Adhesive | Thickness (μm) | 180° Peel Strength (N/cm) | Static Shear Holding Power (min) |

| Double-SidedTissue Tape | T9155 | Acrylic | 150 | ≥7.5 | ≥1440 |

| Double-SidedPET Tape | P8972G | Acrylic | 50 | ≥4.5 | ≥1440 |

| Adhesive Transfer Tape | N506 | Acrylic | 60 | ≥5.2 | 10000 |

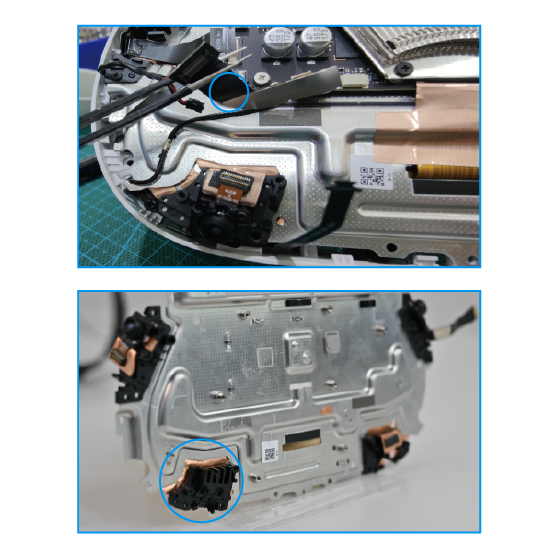

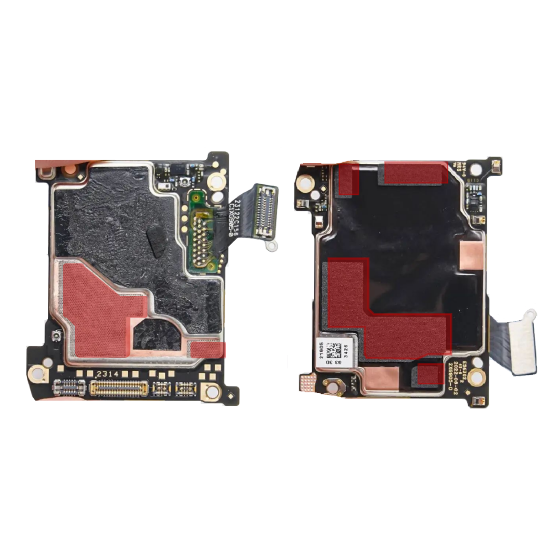

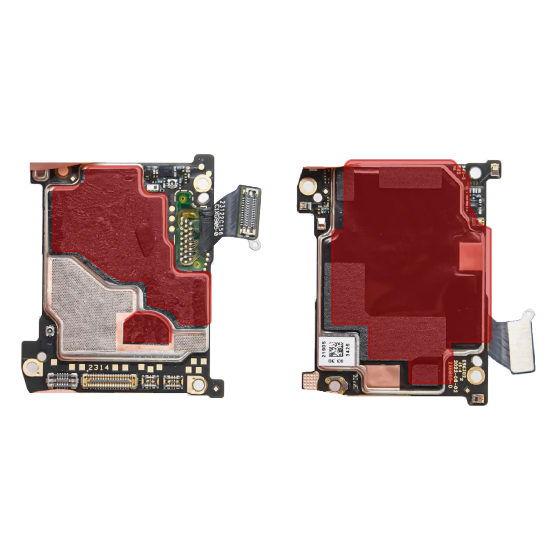

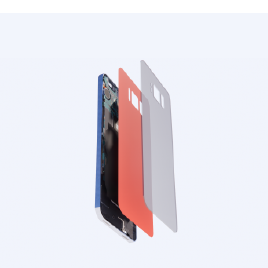

Mainboard Shielding Cover — Conductive Shielding

|

| Product | Grade Name | Thickness(μm) | Carrier | Adhesive | 20min 180°SUSPeel Strength (N/cm) |

| Conductive Adhesive Film | EDxxxxxH | 10~100 | None | Conductive Acrylic | ≥2.8~≥7.6 |

| Conductive Non-woven Fabric Tape | EM8301/EM6301 | 15~100 | Conductive Non-woven Fabric | Conductive Acrylic | ≥2.4~≥6 |

| Conductive Plain Weave Fabric Tape | EM5101/EM6201 | 30~200 | Conductive Plain Weave Fabric | Conductive Acrylic | ≥3.2~≥7.2 |

| Copper Foil Conductive Tape | EM5301/EM6501 | 30~100 | Copper Foil | Conductive Acrylic | ≥4~≥4.8 |

Mainboard Shielding Cover — Graphite Heat Dissipation

|

| Product | Grade Name | Thickness(μm) | Carrier | Color | Adhesive | 20min 180°SUSPeel Strength (N/cm) |

| High Cleanliness Ultra-Thin PET Tape | ST/DTxx | 3~30 | PET | Black/Transparent | Acrylic | 1.2~7.8 |

Middle Frame Encapsulation

|

| Product | Grade Name | Thickness(μm) | Carrier | Adhesive | 20min 180°SUS Peel Strength(N/cm) |

| High-performance Adhesive Transfer Tape | N506/N513 | 60/130 | None | Acrylic | ≥5.2/≥7.5 |

| High-performance PET Tape | P89xxG | 30~160 | PET | Acrylic | ≥3.5~≥9 |

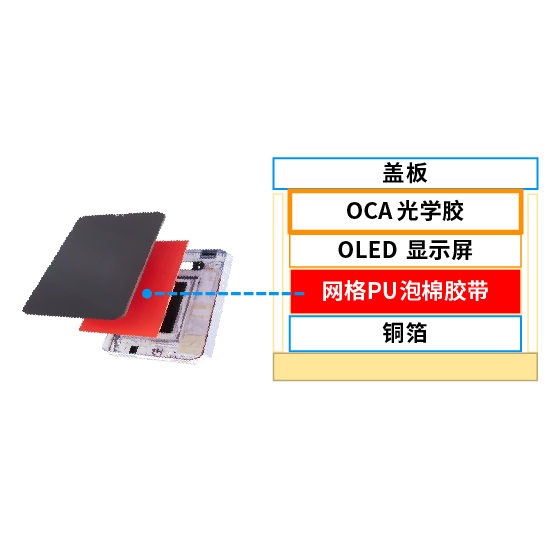

OLED Screen Air Venting Adhesion and Screen Cushioning

|

| Product | Grade Name | Thickness(μm) | Carrier | Adhesive | 20min 180°SUSPeel Strength(N/cm) |

| Mesh PU Foam Tape | CRU-DT1598BG | 150 | PU Foam | Acrylic | A&B:6 |

| SEPA | CRN-DT1xx | 125~135 | None | Special Adhesive | >5.8 |

Screen Optical Bonding

|

| Product | Grade Name | Thickness(μm) | Adhesive | Yellowness Indexb* | Haze | Transmittance(%) |

| OCA | CR-934xGM | 100~250 | Acrylic | ≤0.5 | ≤0.5% | ≥90% |

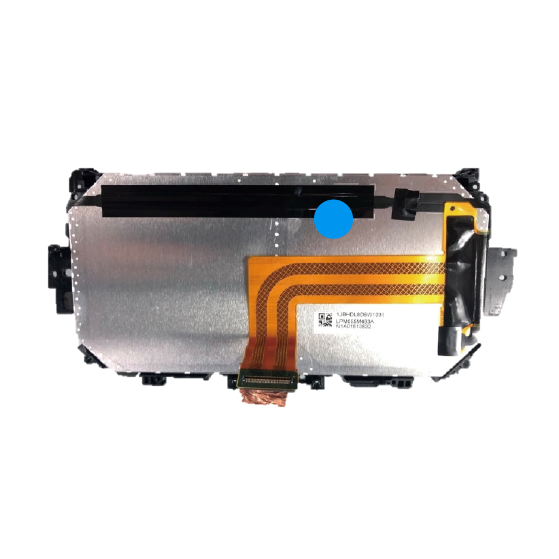

Display Module Shipping Protection

|

| Product | Grade Name | Thickness(μm) | Carrier | Adhesive | Electrical Resistance Performance (Ω) - Film Side / Adhesive Side/Double-Sided | 20min 180°SUSPeel Strength(gf/24mm) |

| PU Protective Film | PUx5xT/B | 60/85 | PET | Polyurethane | / | 0~15 |

| Anti-staticPU Protective Film | PUx5xTA/TB/TE | 48/60/85 | PET | Polyurethane | 10⁶~10¹¹ | 0~15 |

General Carton Sealing Packaging

|

| Product] | Grade Name | Adhesive | Thickness (μm) | 180° Peel Strength (N/cm) | Static Shear Holding Power (min) |

| Double-Sided Tissue Tape | DS513 | Acrylic | 160 | ≥6.3 | ≥1440 |

| Double-Sided Tissue Tape | DS613 | Acrylic | 160 | ≥5.9 | ≥1440 |

| Double-Sided Tissue Tape | T915 | Acrylic | 150 | 10.7 | 10000 |

| Single-Sided Kraft Paper Tape | KT9 | Hot Melt Adhesive | 120 | Summer:≥6.3 Winter:≥5.5 | Summer:≥120 Winter:≥60 |

Edge Packaging Scratch Protection

|

| Product | Grade Name | Adhesive | Thickness (μm) | 180° Peel Strength (N/cm) | Static Shear Holding Power (min) |

| Single-Sided Kraft Paper Tape | KT9 | Hot Melt Adhesive | 120 | Summer:≥6.3 Winter:≥5.5 | Summer:≥120 Winter:≥60 |

Cold-Climate Carton Sealing

|

| Product | Grade Name | Adhesive | Thickness (μm) | 180° Peel Strength (N/cm) | Static Shear Holding Power (min) |

| High-Temperature Resistant Foam Tape | DP1005PWT-TL | Acrylic | 600 | Inner Surface:≥6.7 Outer Surface:≥5.1 | ≥600 |

| High Cold Resistance Tissue Tape | DS703PNH | Acrylic | 160 | Inner Surface:≥6.7 | ≥20 |

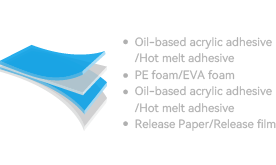

Eco-Friendly Packaging Materials

Bio-Based Double-Sided Tape – Product Features

| Adhesive Transfer Tape – Product Features

|

| Product | Product | Adhesive | Carrier | Thickness (μm) | 180° Peel Strength (N/cm) | Static Shear Holding Power (min) |

| Bio-based Double-Sided Tape | CRT-DT050CB | Bio-based Adhesive | PCR-PET | 50 | 7.2 | >1440 |

| Bio-based Double-Sided Tape | CRT-DT100CB | Bio-based Adhesive | PCR-PET | 100 | 9.5 | >1440 |

| Adhesive Transfer Tape | N506 | Acrylic | / | 60 | ≥5.2 | 10000 |

| Adhesive Transfer Tape | N513 | Acrylic | / | 130 | ≥7.5 | 10000 |

Flying Splice for Paper Jumbo Rolls

|

| Product | Grade Name | Adhesive | Thickness (μm) | 180° Peel Strength (N/cm) | Loop Tack (N) |

| Water-Soluble Tissue Double-Sided Tape | WS0908L | Water-Soluble Adhesive | 85 | ≥2.4 | ≥5 |

Small-Scale Decoration

Product Features

| Application Scenarios

|

| Product | Grade Name | Adhesive | Carrier | Thickness(μm) | Color | Tack (mm) | Adhesion Strength (N/24mm) | Holding Power (min) |

| Tissue Double-Sided Tape | DS10B/G | Oil-based Adhesive | Tissue | 60-160 | Translucent | ≤100-150 | ≥6-13 | ≥60-150 |

| Tissue Double-Sided Tape | DS9 | Water-based Adhesive | Tissue | 70-120 | Translucent | ≤80 | ≥4-10 | ≥180-240 |

| Tissue Double-Sided Tape | DS18 | Hot Melt Adhesive | Tissue | 60-150 | Yellow/White | Summer≥50 Winter≤200 | Summer≥7-16 Winter≥5-14 | Summer≥60-120 Winter≥30-60 |

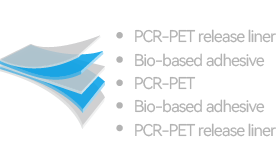

Large-Scale Decoration

Product Features

| Application Scenarios

|

| Product | Grade Name | Adhesive | Carrier | Color | Tack (mm) | Adhesion Strength (N/24mm) | Holding Power (min) |

| Double-Sided Cloth Tape | CSTL160 | Gauze Fiber | White / Brown (Yellow) / Red Paper | 160 | ≥10 | ≥15 | ≥60 |

| Double-Sided Cloth Tape | CSTL200 | Gauze Fiber | White / Brown (Yellow) / Red Paper | 200 | ≥10 | ≥23 | ≥60 |

| Double-Sided Cloth Tape | CSTL220 | Gauze Fiber | White / Brown (Kraft) Paper | 220 | ≥10 | ≥25 | / |

| Double-Sided Cloth Tape | CSTL260 | Gauze Fiber | White / Brown (Kraft) Paper | 260 | ≥10 | ≥25 | / |

| Double-Sided Cloth Tape | CSTL280 | Gauze Fiber | White / Brown (Kraft) Paper | 280 | ≥10 | ≥25 | / |

Outdoor Decoration

Product Features

| Application Scenarios

|

| Product | Grade Name | Adhesive | Carrier | Thickness (μm) | Color | Tack (mm) | Adhesion Strength (N/24mm) | Holding Power (min) |

| Film Double-Sided Adhesive | DS31 | Oil-based Adhesive | PET | 50-150 | Transparent | ≤150-180 | ≥6-13 | ≥120-180 |

| Film Double-Sided Adhesive | DS32 | Oil-based Adhesive | OPP | 50-150 | Transparent | ≤150-180 | ≥6-13 | ≥120-180 |

Press-On Nail Fixation

Product Features

| Application Scenarios

|

| Product | Grade Name | Adhesive | Carrier | Thickness (μm) | Color | Tack (mm) | Adhesion Strength (N/24mm) | Holding Power (min) |

| EPT | H0049 | Acrylic | Adhesive Transfer | 350/400/500 | Transparent | ≥35 | ≥25 | ≥1440 |

| EPT | H0088 | Acrylic | Adhesive Transfer | 350/400/500 | Transparent | ≥25-35 | ≥23-25 | ≥1440 |

| EPT | H0089 | Acrylic | Adhesive Transfer | 350/400/500 | Transparent | ≥35 | ≥25 | ≥1440 |

Anti-Exposure Adhesive Patch

Product Features

| Application Scenarios

|

| Product | Grade Name | Adhesive | Carrier | Thickness (μm) | Color | Tack (mm) | Adhesion Strength (N/24mm) | Holding Power (min) |

| Film Double-Sided Adhesive | DS31 | Oil-based Adhesive | PET | 50-150 | Transparent | ≤150-180 | ≥6-13 | ≥120-180 |

Fabric Positioning

Product Features

| Application Scenarios

|

| Product | Grade Name | Adhesive | Carrier | Thickness (μm) | Color | Tack (mm) | Adhesion Strength (N/24mm) | Holding Power (min) |

| Tissue Double-Sided Tape | DS10 Embroidery | Oil-based Adhesive | Tissue | 95 | Translucent | ≤60 | ≥13 | ≥30 |

| Tissue Double-Sided Tape | DS11 Embroidery | Oil-based Adhesive | Tissue | 100 | Translucent | ≤60 | ≥14 | ≥60 |

Screen Mesh Fixation

Product Features

| Application Scenario

|

| Product | Grade Name | Adhesive | Carrier | Thickness (μm) | Color | Tack (mm) | Adhesion Strength (N/24mm) | Holding Power (min) |

| Tissue Double-Sided Tape | DS512 | Oil-based Adhesive | High-permeability tissue | 140 | Translucent | ≤100 | ≥15 | ≥1440 |

Damage-Free Wall Mounting

Product Features

| Application Scenarios

|

| Product | Grade Name | Adhesive | Carrier | Thickness (μm) | Color | Tack (mm) | Adhesion Strength (N/24mm) | Holding Power (min) |

| EPT | H0056 | Acrylic | Adhesive Transfer | 200/500 | Transparent | ≥20-35 | ≥20-25 | ≥1440 |

| EPT | H0063 | Acrylic | Adhesive Transfer | 1400-2000 | Transparent | ≥30-35 | ≥20-27 | ≥1440 |

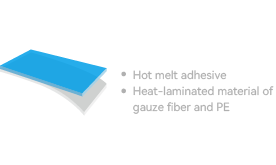

Heavy-Duty Wall Mounting

|

| Product | Grade Name | Adhesive | Carrier | Thickness (μm) | Color | Tack (mm) | Adhesion Strength (N/24mm) | Holding Power (min) |

| Foam Double-Sided Tape | GP12**B/W | Oil-based Adhesive | PE Foam | 600/1100 | Black/White | ≤100 | ≥10 | ≥120 |

| Foam Double-Sided Tape | GP18**B/W | Oil-based Adhesive | PE Foam | 1100 | Black/White | ≤100 | ≥10 | ≥120 |

| Foam Double-Sided Tape | GP2010B | Oil-based Adhesive | PE Foam | 1100 | Black | ≤100 | ≥10 | ≥120 |

| Foam Double-Sided Tape | HP20**B/W | Hot Melt Adhesive | PE Foam | 1000/2000/2500 | Black/White | ≤200 | ≥5 | ≥5 |

| Foam Double-Sided Tape | HP40**B/W | Hot Melt Adhesive | PE Foam | 2000/2500/3000 | Black/White | ≤200 | ≥5 | ≥5 |

| Foam Double-Sided Tape | HE38**B/W | Hot Melt Adhesive | EVA Foam | 1000/1500/2000 | Black/White | ≤200 | ≥5 | ≥5 |

Noise Reduction and Impact Protection

Product Features

| Application Scenarios

|

| Product | Grade Name | Adhesive | Carrier | Thickness (μm) | Color | Tack (mm) | Adhesion Strength (N/24mm) | Holding Power (min) |

| EPT | A30**CST | Acrylic | Adhesive Transfer | 400/500 | Transparent | ≥25-30 | ≥20 | ≥1440 |

Carpet/Floor Film Bonding

Product Features

| Application Scenarios

|

| Product | Grade Name | Adhesive | Carrier | Thickness (μm) | Color | Tack (mm) | Adhesion Strength (N/24mm) | Holding Power (min) |

| Single-Sided Cloth Tape | CDTL170 | Carpet/Flooring Film | Red/Green | Hot Melt Pressure Sensitive Adhesive | 170 | ≥10 | ≥10 | ≥25 |

| Single-Sided Cloth Tape | CDTL220 | Carpet/Flooring Film | Red/Green | Hot Melt Pressure Sensitive Adhesive | 220 | ≥12 | ≥12 | ≥25 |

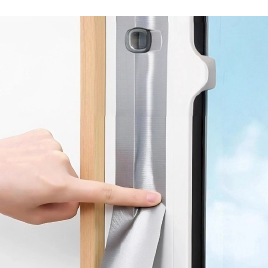

Door and Window Windproofing

Product Features

| Application Scenarios

|

| Product | Grade Name | Adhesive | Carrier | Thickness (μm) | Color | Tack (mm) | Adhesion Strength (N/24mm) | Holding Power (min) |

| Single-Sided Cloth Tape | CDTL150 | Windproof | White/Silver | Hot Melt Pressure Sensitive Adhesive | 150 | ≥10 | ≥10 | ≥20 |

Kitchen Mold Prevention

Product Features

| Application Scenarios

|

| Product | Grade Name | Adhesive | Carrier | Thickness (μm) | Color | Tack (mm) | Adhesion Strength (N/24mm) | Holding Power (min) |

| EPT | A30**CST | Acrylic | Adhesive Transfer | 400/500 | Transparent | ≥25-30 | ≥20 | ≥1440 |

Nameplate Fixation

Product Features

| Application Scenarios

|

| Product | Grade Name | Adhesive | Carrier | Thickness (μm) | Color | Tack (mm) | Adhesion Strength (N/24mm) | Holding Power (min) |

| Double-Sided Foam Tape | GP12**B/W | Oil-based Adhesive | PE Foam | 600/1100 | Black/White | ≤100 | ≥10 | ≥120 |

| Double-Sided Foam Tape | GP18**B/W | Oil-based Adhesive | PE Foam | 1100 | Black/White | ≤100 | ≥10 | ≥120 |

| Double-Sided Foam Tape | GP2010B | Oil-based Adhesive | PE Foam | 1100 | Black | ≤100 | ≥10 | ≥120 |

| Double-Sided Foam Tape | HP20**B/W | Hot Melt Adhesive | PE Foam | 1000/2000/2500 | Black/White | ≤200 | ≥5 | ≥5 |

| Double-Sided Foam Tape | HP40**B/W | Hot Melt Adhesive | PE Foam | 2000/2500/3000 | Black/White | ≤200 | ≥5 | ≥5 |

| Double-Sided Foam Tape | HE38**B/W | Hot Melt Adhesive | EVA Foam | 1000/1500/2000 | Black/White | ≤200 | ≥5 | ≥5 |

Eco-Friendly Packaging

Product Features: Environmentally friendly materials | Recyclable | Attractive and natural appearance | Printable | Writable Application Scenarios: Sealing lightweight packages | Eco-conscious packaging needs | Everyday office or home packing |

| Product | Grade Name | Adhesive | Carrier | Thickness(μm) | Color | Tack(mm) | Adhesion Strength (N/24mm) | Holding Power (min) |

| Kraft Paper Tape | KT19 | Oil-based Adhesive | Kraft Paper | 140 | Earth Yellow | ≤100 | ≥15 | ≥1440 |

| Kraft Paper Tape | KT18G6 | Oil-based Adhesive | Kraft Paper | 140 | Earth Yellow | ≤150 | ≥14 | ≥60 |

| Kraft Paper Tape | KT12 | Water-based Adhesive | Kraft Paper | 120 | Earth Yellow | / | ≥2-10 | ≥180 |

| Kraft Paper Tape | KT8/9 | Hot Melt Adhesive | Kraft Paper | 120 | White/Brown Yellow | Summer≥50 Winter≤200 | Summer≥15 Winter≥14 | Summer≥120 Winter≥60 |

| Kraft Paper Tape | KT10 | Hot Melt Adhesive | Kraft Paper | 130 | Earth Yellow | Summer≥50 Winter≤200 | Summer≥16 Winter≥15 | Summer≥120 Winter≥60 |

| Kraft Paper Tape | KT25 | Hot Melt Adhesive | 夹筋Kraft Paper | 160 | Earth Yellow | Summer≥50 Winter≤200 | ≥12 | ≥30 |

Heavy-Duty Packaging

Product Features

| Application Scenarios

|

| Product | Grade Name | Adhesive | Carrier | Thickness (μm) | Color | Tack (mm) | Adhesion Strength (N/24mm) | Holding Power (min) |

| Single-Sided Cloth Tape | CDTL200 | Hot Melt Pressure Sensitive Adhesive | General-purpose/Box Sealing | 200 | Red/Green/Blue/Brown/Silver/Black/White | ≥10 | ≥12 | ≥25 |

| Single-Sided Cloth Tape | CDWL250 | Hot Melt Pressure Sensitive Adhesive | General-purpose/Box Sealing | 250 | Red/Green/Blue/Brown/Silver/Black/White | ≥12 | ≥13 | ≥30 |

| Single-Sided Cloth Tape | CDWL270 | Hot Melt Pressure Sensitive Adhesive | General-purpose/Box Sealing | 270 | Red/Green/Blue/Brown/Silver/Black/White | ≥12 | ≥14 | ≥30 |

Documents and Files

Product Features

| Application Scenarios

|

| Product | Grade Name | Adhesive | Carrier | Thickness (μm) | Color | Tack(mm) | Adhesion Strength (N/24mm) | Holding Power(min) |

| Tissue Double-Sided Tape | DS10B/G | Oil-based Adhesive | Tissue | 60-160 | Translucent | ≤100-150 | ≥6-13 | ≥60-150 |

| Tissue Double-Sided Tape | DS9 | Water-based Adhesive | Tissue | 70-120 | Translucent | ≤80 | ≥4-10 | ≥180-240 |

| Tissue Double-Sided Tape | DS18 | Hot Melt Adhesive | Tissue | 60-150 | Yellow/White | Summer≥50 Winter≤200 | Summer≥7-16 Winter≥5-14 | Summer≥60-120 Winter≥30-60 |

Packaging Sealing

Product Features

| Application Scenarios

|

| Product | Grade Name | Adhesive | Carrier | Thickness(μm) | Color | Tack(mm) | Adhesion Strength (N/24mm) | Holding Power(min) |

| Film Double-Sided Adhesive | DS31 | Oil-based Adhesive | PET | 50-150 | Transparent | ≤150-180 | ≥6-13 | ≥120-180 |

| Film Double-Sided Adhesive | DS32 | Oil-based Adhesive | OPP | 50-150 | Transparent | ≤150-180 | ≥6-13 | ≥120-180 |

Fixing of elevator stiffeners

| The fixing of the reinforcing rib can effectively prevent the deformation of the car wall caused by external force impact. |

| Product | Grade Name | Carrier | Color | Thickness(μm) | ProductStructure | Release Liner |

| PE Foam Tape | DP1010B/W | PE Foam | Black/White | 1100 | Triple-layer | Release Paper |

| EPT | A7080BR | Acrylic Foam | Black | 800 | Single-layer | Red PE Film |

| EPT | A7110BT-1DL | Acrylic Foam | Black | 1100 | Triple-layer | PET Release Film |

| EPT | A7110WT-1D | Acrylic Foam | White | 1100 | Triple-layer | PET Release Film |

| EPT | A7064WR | Acrylic Foam | White | 640 | Single-layer | Red PE Film |

| EPT | A7120WR | Acrylic Foam | White | 1200 | Single-layer | Red PE Film |

| EPT | A7200WR | Acrylic Foam | White | 2000 | Single-layer | Red PE Film |

| EPT | A7080FR | Acrylic Foam | Gray | 800 | Single-layer | Red PE Film |

| EPT | A7040FR | Acrylic Foam | Gray | 400 | Single-layer | Red PE Film |

Mirror fixed

|

| Product | Grade Name | Carrier | Color | Thickness (μm) | Peel Strength on Steel (180° Peel,20min)N/24mm | Static Shear Holding Power (24mm*24mm)min | Dynamic Shear (24mm*24mm,20min)N | ProductStructure | Release Liner |

| PE Foam Tape | DP1010B/W | PE Foam | Black/White | 1100 | ≥13 | ≥1440 | / | Triple-layer | Release Paper |

The decorative panel is fixed

|

| Product | Grade Name | Carrier | Color | Thickness (μm) | Peel Strength on Steel (180° Peel,20min)N/24mm | Static Shear Holding Power (24mm*24mm)min | Dynamic Shear (24mm*24mm20min)N | Structure | Release Liner |

| A7040FR-2D | EPT | Acrylic Foam | Gray | 400 | ≥32 | ≥1440 | ≥400 | Triple-layer | PET Release Film |

| 7965G | PET Double-Sided Tape | PET | Transparent | 205 | ≥17 | ≥1440 | Triple-layer | Brown Glassine Paper |

Fixation of parts and trims

|

| Product | Grade Name | Carrier | Color | Thickness (μm) | Peel Strength on Steel (180° Peel Strength,20min)N/24mm | Static Shear Holding Power (24mm*24mm)min | Dynamic Shear (24mm*24mm,20min)N | Structure | Release Liner |

| PE Foam Tape | DP1010B/W | PE Foam | Black/White | 1100 | ≥13 | ≥1440 | Triple-layer | Release Paper | |

| EPT | A7064WR | Acrylic Foam | White | 640 | ≥32 | ≥1440 | ≥300 | Single-layer | Red PE Film |

Door panel bonding

|

| Grade Name | Product | Carrier | Color | Thickness (μm) | Peel Strength on Steel (180° Peel,20min)N/24mm | Static Shear Holding Power (24mm*24mm)min | Dynamic Shear (24mm*24mm20min)N | Structure | Release Liner |

| P8967LEH | Thin Double-Sided Tape | PET | Transparent | 170 | ≥17 | ≥1440 | Triple-layer | Release Paper |

The bottom plate of the lift car is fixed

|

| Product | Grade Name | Carrier | Color | Thickness(μm) | Peel Strength on Steel (180° Peel Strength,20min)N/24mm | Static Shear Holding Power 24mm*24mm)min | Dynamic Shear (24mm*24mm,20min)N | Structure | Release Liner |

| EPT | A7040FR | PE Foam | Gray | 400 | ≥30 | ≥1440 | ≥300 | Single-layer | Red PE Film |

| EPT | A7064FR | Acrylic Foam | Gray | 640 | ≥30 | ≥1440 | ≥300 | Single-layer | Red PE Film |

| EPT | A7120FR | Acrylic Foam | Gray | 1200 | ≥35 | ≥1440 | ≥300 | Single-layer | Red PE Film |

| EPT | A7150FR | Acrylic Foam | Gray | 1500 | ≥35 | ≥1440 | ≥300 | Single-layer | Red PE Film |

Ground bonding

|

| Product | Grade Name | Carrier | Color | Thickness (μm) | Peel Strength on Steel (180° Peel Strength,20min)N/24mm | Static Shear Holding Power (24mm*24mm)min | Dynamic Shear (24mm*24mm20min)N | Structure | Release Liner |

| PVC Flooring Tape | T914/T914NS | Nonwoven Fabric | Transparent | 140 | ≥23 | 10000 | - | Triple-layer | Release Paper |

Skirting edge strip bonding

|

| Product | Grade Name | Carrier | Color | Thickness (μm) | Peel Strength on Steel (180° Peel Strength,20min)N/24mm | Static Shear Holding Power (24mm*24mm)min | Dynamic Shear (24mm*24mm20min)N | Structure | Release Liner |

| EPT | A7080BR3-3D | Acrylic Foam | Black | 800 | ≥35 | ≥1440 | ≥300 | Single-layer | PE Release Film |

Temporary fixation of computer embroidery process

|

| Product | Grade Name | Adhesive | Thickness(μm) | Tack(mm) | Adhesion Strength(N/24MM) | Adhesion Holding Power(hour) |

| Tissue Tape | DS10B3 | Oil-Based Acrylic | 90-100 | ≤120 | Inner Surface≥10 | Inner Surface≥30 |

| Tissue Tape | DS11D | Oil-Based Acrylic | 90 | ≤70 | Inner Surface≥8 | Inner Surface≥60 |

| Tissue Tape | DS22C | Hot Melt Adhesive | 145/155 | ≤180 | ≥22/≥23 | Summer≥4 |

Leather sewing positioning

|

| Product | Grade Name | Adhesive | Thickness(μm) | Tack(mm) | Adhesion Strength(N/24MM) | Adhesion Holding Power(hour) |

| Tissue Tape | DS10B6# | Oil-Based Acrylic | 70-120 | ≤100 | ≥9-14 | ≥60 |

Temporary fixation of lining of luggage by sewing

| The utility model has the characteristics of strong stickiness, good adherence and the like, has good sticking effect on the box body and the lining cloth, and prevents the lining from falling off during sewing |

| Product | Grade Name | Adhesive | Thickness(μm) | Tack(mm) | Adhesion Strength(N/24MM) | Adhesion Holding Power(hour) |

| Tissue Tape | DS10WW | Oil-Based Acrylic | 80-150 | ≤150 | ≥14-21 | ≥60 |

| Tissue Tape | DS18 | Hot Melt Adhesive | 60-160 | Summer ≥100 Winter ≤120 | Summer≥12-15 Winter≤8-21 | Summer≥2 Winter≤0.8 |

Sticky hair in the garment industry

|

| Product | Grade Name | Adhesive | Thickness(μm) | Tack(mm) | Adhesion Strength(N/24MM) | Adhesion Holding Power(hour) |

| Kraft Paper Tape | KT11 | Hot Melt Adhesive | 130 | Summer≥100 Winter≤150 | Summer≥22 Winter≤20 | Summer≥3 Winter≤1.5 |

Fixation of carriage parts

| Product advantage: High and low temperature resistance, adapt to different temperature and humidity environment changes. It has anti-seismic and anti-jitter performance, taking into account the filling effect.. Normal operation in low temperature environment (0 ° C) meets EU ROHS2.0 environmental protection requirements. |

| Application scenario: It reliably bonds carriage parts, trailer stands, truck panels, silencing cotton, and metal components—even in low winter temperatures—ensuring safety during transport, assembly, and use. |

| Product | Grade Name | Color | Thickness (μm) | Peel Strength on Steel (180° Peel) 72h(N/25mm) | Static Shear Holding Power (24mm*24mm)23℃, 1000g(min) | Dynamic Shear (24mm*24mm) 72h(N) | Loop Tack (24mm*24mm) (N) | Temperature Resistance | Structure | Release Liner |

| EPT | A7200WR-N | White | 2000 | 62 | >1440 | 665 | 28 | -20℃-80℃ | Single-layer | Red PE Film |

| EPT | A7110BR3-3D | Black | 1100 | 50 | >1440 | / | 80 | -20℃-80℃ | Triple-layer | Red PE Film |

| EPT | A7110F-1D | Gray | 1100 | >45 | >1440 | >400 | >45 | -20℃-80℃ | Triple-layer | Release Paper |

| EPT | A7100WR | White | 1000 | 58 | >1440 | 754 | 50 | -20℃-80℃ | Single-layer | Red PE Film |

Seat Heater and Seat Cushion Foam Bonding

|

| Product | Grade Name | Thickness( mm) | Carrier | Peel Strength on Steel(N/ 24mm) | Static Shear Holding Power(min) | Tack(mm) |

| Low-Odor, Low-VOC Tape | VW606Series | 0 . 1 - 0 . 16 | Tissue | ≥10 | ≥10 | ≤180 |

| Low-Odor, Low-VOC Tape | VS10B6Y | 0 . 14 | Tissue | ≥19 | ≥20 | ≤100 |

| Low-Odor, Low-VOC Tape | DS10B6Y | 0 . 14 | Tissue | ≥23 | ≥100 | ≤120 |

Roof molding bonding

|

| Products | Model | Color | Thickness (mm) | Structure | Characteristic |

| EPT | A7xxxFR3-D Series | Grey | 0.4-1.1 | Three floors | Super sticky |

Cover Glass to Touch Panel Bonding

|

| Product | Grade Name | Thickness(μm) | Adhesive | Refractive Index | TransmittanceT | Yellowness Indexb* | Haze |

| Full Lamination OCA | CR-734xP | 100-250 | Acrylic | 1.49 | >90% | <0.4% | <0.4% |

| Full Lamination OCA | CR-934xGM/N | 100-200 | Acrylic | 1.49 | >90% | <0.4% | <0.4% |

| Full Lamination OCA | CR-724xVC | 100-200 | Acrylic | 1.49 | >90% | <0.4% | <1% |

Bumper trim bonding

|

| Product | Grade Name | Color | Thickness(mm) | Structure | Features |

| EPT | A7xxxFR3-D Series | Gray | 0.4-1.1 | Triple-layer | Ultra-high tack |

Adhesive bonding of foam for air outlet pipe and air outlet of air conditioner

| Product | Grade Name | Thickness( mm ) | Carrier | Peel Strength on Steel( N/24mm) | Static Shear Holding Power(min) | Tack(mm) |

| Low-Odor, Low-VOC Tape | VW606Series | 0 1 -0 . 1 6 | Tissue | ≥10 | ≥144 0 | ≤180 |

| Low-Odor, Low-VOC Tape | VS606Series | 0 . 1 -0 . 1 5 | Tissue | ≥13 | ≥600 | ≤100 |

| Low-Odor, Low-VOC Tape | DS606Series | 0 . 1 2 5 -0 . 1 6 | Tissue | ≥16 | ≥600 | ≤100 |

| Low-Odor, Low-VOC Tape | DS601Series | 0 . 1 3 -0 . 1 6 | Tissue | ≥13 | ≥600 | ≤100 |

| Low-Odor, Low-VOC Tape | DS10WWSeries | 0 . 0 8 - 0 . 1 6 | Tissue | ≥10 | ≥60 | ≤150 |

| Low-Odor, Low-VOC Tape | DS10CCSeries | 0 . 0 9 -0 . 1 6 | Tissue | ≥10 | ≥120 | ≤150 |

Touch Panel to Display Module Bonding

|

| Product | Grade Name | Thickness(μm) | Adhesive | Refractive Index | Transmittance T | Yellowness Indexb* | Haze |

| Full Lamination OCA | CR-734xP | 100-250 | Acrylic | 1.49 | >90% | <0.4% | <0.4% |

| Full Lamination OCA | CR-934xGM/N | 100-200 | Acrylic | 1.49 | >90% | <0.4% | <0.4% |

| Full Lamination OCA | CR-724xVC | 100-200 | Acrylic | 1.49 | >90% | <0.4% | <1% |

Anti-collision strip Bonding

|

| Product | Grade Name | Color | Thickness(mm) | Structure | Features |

| EPT | A7xxxFR3-D Series | Gray | 0.4-1.1 | Triple-layer | Ultra-high tack |

A/B pillar foam bonding

|

| Product | Grade Name | Thickness(mm) | Carrier | Peel Strength on Steel( N/24mm) | Static Shear Holding Power( m i n ) | Tack( m m ) |

| Low-Odor, Low-VOC Tape | VS606Series | 0 . 1 -0 . 1 5 | Tissue | ≥13 | ≥600 | ≤100 |

| Low-Odor, Low-VOC Tape | DS606Series | 0 . 1 2 5 - 0 . 1 6 | Tissue | ≥16 | ≥600 | ≤100 |

| Low-Odor, Low-VOC Tape | DS601Series | 0 . 1 3 -0 . 1 6 | Tissue | ≥13 | ≥600 | ≤100 |

| Low-Odor, Low-VOC Tape | DS10WW Series | 0 . 0 8 -0 . 1 6 | Tissue | ≥10 | ≥60 | ≤150 |

| Low-Odor, Low-VOC Tape | DS10CC Series | 0 . 0 9 -0 . 1 6 | Tissue | ≥10 | ≥120 | ≤150 |

| Low-Odor, Low-VOC Tape | VW606 Series | 0 . 0 6 -0 . 1 6 | Tissue | ≥10 | ≥10 | ≤180 |

Display Frame Bonding

|

| Product | Grade Name | Thickness (mm) | Peel Strength on Steel Force 20min, (N/24mm) | Adhesion to PC Sheet 20min, (N/24mm) | Adhesion to PP Sheet 20min, (N/24mm) | Dynamic Shear 20min, (N) | Loop Tack (N) |

| Acrylic Foam Tape | A7110BT-1DL | 1.1 | ≥50 | ≥50 | ≥20 | ≥400 | ≥50 |

Lower pedal/guard plate of door bonding

|

| Product | Grade Name | Color | Thickness(mm) | Structure | Features |

| EPT | A7xxxFR3-DSeries | Gray | 0.4-1.1 | Triple-layer | Ultra-high tack |

Bonding of trunk/body carpet

|

| Product | GradeName | Thickness ( mm) | Carrier | PeelStrengthonSteel ( N/ 24mm) | StaticShearHoldingPower ( min) | Tack ( mm) |

| Low-Odor,Low-VOCTape | NV767Series | 0 . 07 - 0 . 1 | AdhesiveTransfer | ≥13 | ≥240 | ≥50 |

| Low-Odor,Low-VOCTape | NC0707 | 0 . 07 | AdhesiveTransfer | ≥15 | ≥240 | ≤100 |

| Low-Odor,Low-VOCTape | NC767W | 0 . 1 | AdhesiveTransfer | ≥13 | 23℃ : ≥1440 80℃ : ≥30 | ≤100 |

FPC Bonding

|

| Product | Grade Name | Thickness(mm) | Carrier | Adhesion to SUS (N/cm) | Static Shear Holding Power (min) | Tack (Rolling Ball) | Temperature Resistance (℃) |

| High-performance Adhesive Transfer Tape | N5(X)Series | 0.06、0.13 | Adhesive Transfer | ≥5.2 | RT 10000 | / | Short-term:205 Long-term:80 |

| High-performance PET Tape | T9(X)Series | 0.12-0.16 | Tissue | 9.4 | RT 10000 | 14# | -40~80 |

Shark Fin/Trim Tail Attachment

|

| Product | Grade Name | Color | Thickness(mm) | Structure | Features |

| EPT | A7xxxFR3-D Series | Gray | 0.4-1.1 | Triple-layer | Ultra-high tack |

Bonding of ETC, car perfume, mobile phone bracket, driving recorder and other accessories

|

| Products | Model | Thickness (mm) | Carrier | Adhesion to steel plate (180 ° stripping) (N/24mm) | Adhesion to PC board (180 ° stripping) (N/24mm) | Adhesion to PP plate (180 ° stripping) (N/24mm) | Dynamic shear force (24mm*24mm) | Ring initial bonding (24mm * 24mm) |

| EPT | A7110BT-1DL | 1.1 | Acrylic foam | ≥50 | ≥50 | ≥20 | ≥400 | ≥50 |

EMI Shielding

|

| Product | Thickness (mm) | Resistance in the XY Direction/RT | Resistance in the Z Direction/RT | Resistance in the XY Direction/85℃85%RH | Resistance in the Z Direction/85℃85%RH | High Temperature 70°C Holding Power/500g |

| Conductive Plain Weave Fabric Series | 0.2-0.4 | ≤100mΩ | ≤30mΩ | ≤100mΩ | ≤30mΩ | ≥72h |

| Conductive Nonwoven Fabric Series | 0.03-0.1 | ≤100mΩ | ≤20mΩ | ≤100mΩ | ≤20mΩ | ≥72h |

B/C pillar trim panel bonding

|

| Product | Grade Name | Color | Thickness (mm) | Structure | Features |

| EPT | A7xxxFR3-D Series | Gray | 0.4-1.1 | Triple-layer | Ultra-high tack |

Conductive Grounding

|

| Product | Thickness (mm) | Resistance in the XY Direction/RT | Resistance in the Z Direction/RT | Resistance in the XY Direction/85℃85%RH | Resistance in the Z Direction/85℃85%RH | High Temperature 70°C Holding Power/500g |

| Conductive Plain Weave Fabric Series | 0.2-0.4 | ≤100mΩ | ≤30mΩ | ≤100mΩ | ≤30mΩ | ≥72h |

| Conductive Nonwoven Fabric Series | 0.03-0.1 | ≤100mΩ | ≤20mΩ | ≤100mΩ | ≤20mΩ | ≥72h |

Radar bonding

|

| Product | Grade Name | Color | Thickness(mm) | Structure | Features |

| EPT | A7xxxBT-1DLSeries | Black | 0.25-1.1 | Triple-layer | Low Surface Energy (LSE) Bonding |

Screen Protection

|

| Product | Grade Name | Color | Thickness (μm) | Carrier | Anti-static Value (Ω) | Peel-off Voltage (V) |

| PU Protective Film | PU55(X)T/G | Transparent | 60-85 | PET | / | / |

| PU Protective Film | PU(X)T(X) | Transparent | 60-85 | PET | 膜抗108 | / |

| PU Protective Film | PU(X)TGB | Transparent | 60-85 | PET | 胶抗109 | <500 |

| PU Protective Film | PU(X)TGB | Transparent | 60-85 | PET | 胶抗109 | <500 |

Door sealing strip bonding

|

| Product | Grade Name | Color | Thickness(mm) | Structure | Features |

| EPT | A7xxxBT-1DLSeries | Black | 0.25-1.1 | Triple-layer | Low Surface Energy (LSE) Bonding |

Hub balance lead block bonding

|

| Product | Grade Name | Color | Thickness(mm) | Structure | Features |

| EPT | A7xxxFR Series | Gray | 0.4-1.2 | Single-layer | Strong Adhesion |

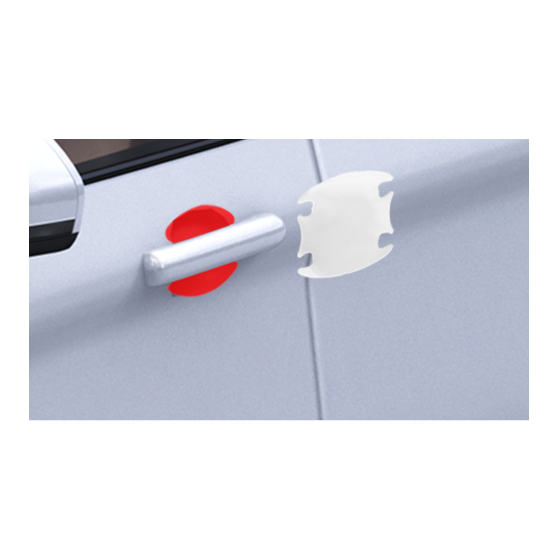

Auxiliary fixing of door handle

|

| Product | Grade Name | Color | Thickness(mm) | Structure | Features |

| EPT | A7xxxFR Series | Gray | 0.4-1.2 | Single-layer | Strong Adhesion |

Wheel arch bonding

|

| Product | Grade Name | Color | Thickness(mm) | Structure | Features |

| EPT | A7xxxFR Series | Gray | 0.4-1.2 | Single-layer | Strong Adhesion |

Automobile plate bonding

|

| Product | Grade Name | Color | Thickness(mm) | Structure | Features |

| EPT | H0053 | Dark Gray | 0.8 | Single-layer | Strong Peel Force |

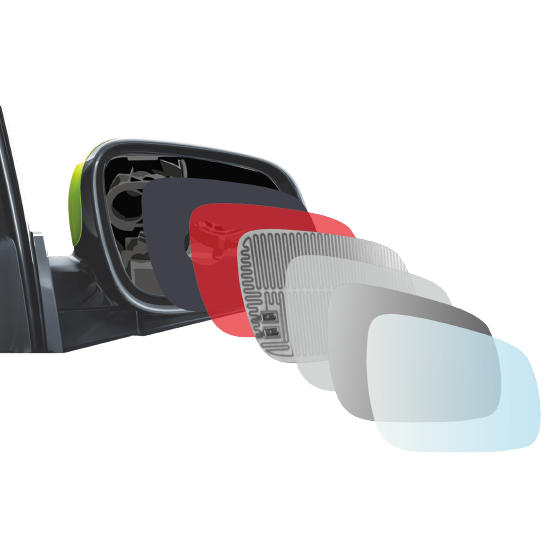

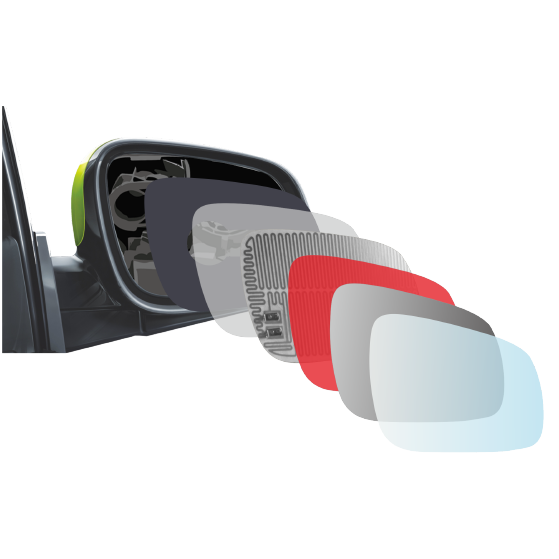

Bon between that mirror support and the resistor sheet

|

| Product | Grade Name | Carrier | Adhesive | ProductColor | Thickness(mm) | Temperature Resistance | Notes |

| Tissue Tape | DS713M | Tissue | Acrylic | Translucent | 0.16 | 80℃ | Backsheet Adhesive |

| PE Foam Tape | DP1005BM | PE Foam | Acrylic | Black | 0.6 | 80℃ | Mirror Adhesive |

Bonding of resistor and lens

|

| Product | Grade Name | Carrier | Adhesive | Product Color | Thickness(mm) | Temperature Resistance | Notes |

| PET Tape | DS31-5012 | PET | Acrylic | Transparent/Black | 0.09 | 80℃ | Mirror Adhesive |

| CPP Tape | DS33-6050M | CPP | Acrylic | Off-white | 0.24 | 80℃ | Backsheet Adhesive |

Bonding between lens and holder

|

| Product | Grade Name | Carrier | Adhesive | ProductColor | Thickness(mm) | Temperature Resistance | Notes |

| PE Foam Tape | DP1005BM | PE Foam | Acrylic | Black | 0.6 | 80℃ | Mirror Adhesive |

| CPP Tape | DS33-6050M | CPP | Acrylic | Off-white | 0.24 | 80℃ | Backsheet Adhesive |

| PET Tape | DS31-6100BM | PET | Acrylic | Transparent/Black | 0.2 | 80℃ | Backsheet Adhesive |

Interior foam bonding

产品特点

|

| Products | Model | Carrier | Type of glue | Use | Thickness (mm) | Flame retardant rating |

| Flame retardant tape | DS10WWF | Tissue | Acrylic acid flame retardant glue | Felt/foam 60 ℃ anti-curved surface | 0.13 | UL-94 VTM-0 |

| Flame retardant tape | DS10B6F-A Series | Tissue | Acrylic acid flame retardant glue | Felt/foam flat tape | 0.12-0.16 | UL 94 VTM-0 |

| Flame retardant tape | DS10BF Series | Tissue | Acrylic acid flame retardant glue | Felt/foam flat tape | 0.1-0.15 | UL 94 VTM-0 |

Battery flame-retardant material bonding

产品特点

|

| Products | Model | Carrier | Type of glue | Use | Thickness (mm) | Flame retardant rating |

| Flame retardant tape | DS10B6F-A Series | Tissue | Acrylic acid flame retardant glue | Felt/foam flat tape | 0.12-0.16 | UL 94 VTM-0 |

| Flame retardant tape | DS10BF Series | Tissue | Acrylic acid flame retardant glue | Felt/foam flat tape | 0.1-0.15 | UL 94 VTM-0 |

| Flame retardant tape | DS31-6005FHA | PET | Acrylic acid flame retardant glue | Felt/foam flat tape | 0.05 | UL 94 VTM-0 |

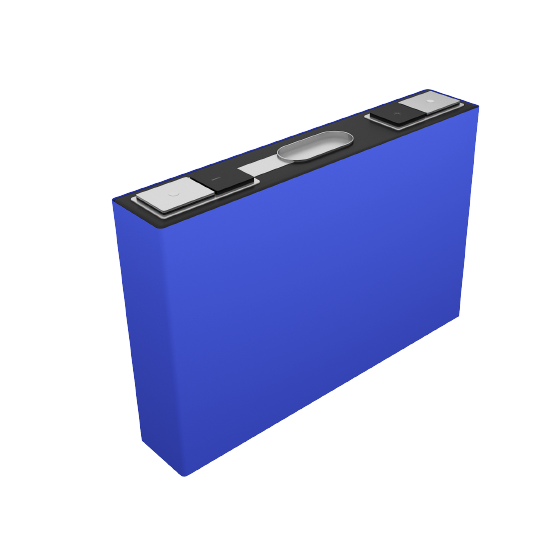

Battery Insulation Wrapping

General-Purpose Blue Film: Flame retardancy meets UL94 V-0 standard (tested on 2mm aluminum foil); Meets national standards for electrical performance (leakage current, puncture resistance, and resistivity); Maintains adhesion on battery folded edges at both room temperature and 80 °C without popping open; No adhesive residue when peeled off after 7 days at room temperature; High tape tack for strong adhesion. High-Shear Blue Film: High shear strength and strong adhesion; maintains bonding under complex stress conditions; Superior electrical insulation compared to standard wrapping tapes, helping to isolate individual cell failures; |

| Product | Grade Name | Carrier | Adhesive | Thickness(μm) | Shear Strength(Mpa) |

| Universal Blue Film | CL-8210-S | PET | Acrylic | 100 | / |

| Universal Blue Film | CL-8211-S | PET | Acrylic | 110 | / |

| High Shear Insulation Film | CRT-DT1101LU | PET | Acrylic | 110 | ≥7 |

| High Shear Insulation Film | CRT-DT0803LU | PET | Acrylic | 80 | ≥7 |

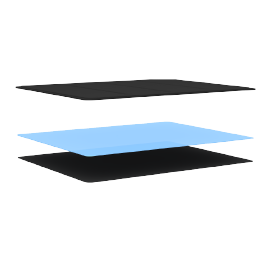

Bonding of Insulation Materials Between Battery Cells (Mica Sheets, PC Sheets, Foam, Aerogel)

|

| Product | Grade Name | Carrier | Adhesive | Thickness(μm) | Flame Resistance Class |

| Flame Retardant Tape | DS10BFSeries | Tissue | Acrylic | 100-140 | VTM-0 |

| Flame Retardant Tape | DS10WWF | Tissue | Acrylic | 130 | VTM-0 |

| Flame Retardant Tape | DS31-6xxxFSeries | PET | Acrylic | 50/100/200 | VTM-0 |

| Flame Retardant Tape | NC767F | Adhesive Transfer | Acrylic | 50 | VTM-0 |

| Aerogel Encapsulation Tape | TS2510ACJ | PET | Epoxy | 35 | VTM-2 |

| Aerogel Encapsulation Tape | TS3614ACJ | PET | Epoxy | 50 | VTM-2 |

Bonding of Flame-Retardant Materials in Modules (PC Sheets, Foam, Mica Sheets, etc.)

Flame-Retardant Tape: Excellent flame-retardant performance, compliant with UL94 VTM-0 standard; High tack and strong bonding strength; Heat-resistant and aging-resistant, suitable for a wide range of applications; Outstanding electrical insulation properties; Complies with environmental regulations (halogen-free). Mica Bonding Tape: Excellent wet-out performance; conforms well to uneven surfaces; Strong adhesion to mica materials; Easy-release liner design prevents adhesive lift-off during removal; Good resistance to harsh environmental conditions. |

| Product | Grade Name | Carrier | Adhesive | Thickness(μm) | Flame Resistance Class |

| Flame Retardant Tape | DS10BF-100 | Tissue | Acrylic | 100 | VTM-0 |

| Flame Retardant Tape | DS31-6005FHA | PET | Acrylic | 50 | VTM-0 |

| Flame Retardant Tape | NC767F | Adhesive Transfer | Acrylic | 50 | VTM-0 |

| Mica Bonding Tape | 69xxxYMHSeries | PET | Acrylic | 100-140 | / |

| Mica Bonding Tape | DS5xxxYMHSeries | Tissue | Acrylic | 100-140 | / |

FPC Bonding

| Crown New Materials High-Performance Tape Series, Compared to traditional products, this series offers enhanced performance across multiple aspects. It is ideal for applications with higher bonding requirements and effectively addresses bonding challenges across a wide range of materials. |

| Product | Grade Name | Carrier | Adhesive | Thickness (μm) | Peel Strength (N/cm) | Static Shear Holding Power(min) |

| High-performance Adhesive Transfer Tape | N506 | Adhesive Transfer | Acrylic | 60 | ≥13(N/24mm) | 10000 |

| High-performance Adhesive Transfer Tape | N513 | Adhesive Transfer | Acrylic | 130 | ≥18(N/24mm) | 10000 |

Side Panel Insulation

|

| Product | Grade Name | Carrier | Adhesive | Thickness (μm) | Flame Resistance Class | T-Type Peel Strength After Heat Pressing(90°) (N/24mm) |

| Side Panel Heat Press Film | TS10050 | PET | Epoxy | 130 | VTM-0 | ≥12 |

Foam Bonding

|

| Product | Grade Name | Carrier | Adhesive | Thickness(μm) | Flame Resistance Class |

| Flame Retardant Tape | DS10BF-100 | Tissue | Acrylic | 100 | VTM-0 |

| Flame Retardant Tape | DS31-6005FHA | PET | Acrylic | 50 | VTM-0 |

| Flame Retardant Tape | NC767F | Adhesive Transfer | Acrylic | 50 | VTM-0 |

Adhesive Bonding for EV Charging Gun and Charging Pile

|

| Product | Grade Name | Carrier | Adhesive | Thickness (μm) | Shear Strength on Blue Film (Mpa) | Peel Strength (N/24mm) |

| High-Strength Double-Sided Tape | NC703L | Adhesive Transfer | Acrylic | 30 | ≥1.5 | ≥10 |

| High-Strength Double-Sided Tape | CRT-DP0507CT | PET | Acrylic | 50 | ≥1.5 | ≥9 |

| High-Strength Double-Sided Tape | CRT-DP1007CT | PET | Acrylic | 100 | ≥1.5 | ≥13 |

| High-Strength Double-Sided Tape | CRT-DP1507CT | PET | Acrylic | 150 | ≥1.5 | ≥15 |

| High-Strength Double-Sided Tape | CRT-DP2007CT | PET | Acrylic | 200 | ≥1.5 | ≥17 |

Bonding of Glass Cover to Charging Pile

|

| Product | Grade Name | Carrier | Adhesive | Thickness (μm) | Peel Strength (N/24mm) | Shear Strength (Mpa) |

| EPT(Acrylic Foam Tape) | A7110FR | Acrylic Foam | Acrylic | 1100 | ≥24 | ≥1 |

| EPT(Acrylic Foam Tape) | A7230FR | Acrylic Foam | Acrylic | 2300 | ≥24 | ≥1 |

| EPT(Acrylic Foam Tape) | A7040F-4 | Acrylic Foam | Acrylic | 400 | (Adhesion to PET Blue Film)>8 | ≥1.5 |

Conventional bonding application

| Conventional bonding refers to the use of adhesive tape to secure electronic components, housings, or assemblies to meet the requirements for stability, durability, and safety in electronic products. |

| Products | Series | Model | Thickness (μm) | Carrier | Color | 180 ° peel force (GF/25mm) |

| Substrate-free tape | Regular series | NCX | 50/130 | / | Transparent | 1000-1500 |

| Tissue tape | Series 5 | DS5X/L/G | 100-160 | Tissue | Translucent | 1000-2600 |

| Tissue tape | 6 series | DS6X | 100-400 | Tissue | Translucent | 1000-2400 |

| Tissue tape | Series 7 | DS7X | 130-160 | Tissue | Translucent | 1300-2000 |

| PET tape | Regular series | 79X | 30-245 | PET | Clear/Black | 600-3000 |

| PET tape | Die cutting dry | 69XLE | 30-100 | PET | Clear/Black | 600-1200 |

High-performance bonding application

|

| Products | Series | Model | Thickness (μm) | Carrier | Color | 180 ° peel force (GF/25mm) |

| High-performance substrate-free adhesive tap | N5 series | N5X | 60/130 | / | Transparent | 2500/3000 |

| High performance tissue tape | T9 series | T9X | 120-160 | Tissue | Translucent | 2000-3000 |

| High performance PET tape | Balanced series | P89X2G | 50-100 | PET | Transparent | 1500-2400 |

| High performance PET tape | LSE Series | P89xxLE/A | 100-200 | PET | Transparent | 1500-2000 |

| High performance PET tape | Anti-rebound series | P89X21G | 50-100 | PET | Transparent | 1500-2400 |

| High performance PET tape | High Peel Series | P89X22G | 50-100 | PET | Transparent | 1800-3000 |

Special bonding application

|

| Product | Grade Name | Carrier | Thickness(μm) | ProductColor | 180° Peel Strength(gf/25mm) |

| Chemical-Resistant Tape | CRT-DTXXXBCR | PET | 50-200 | Transparent/Black | 1400-2500 |

| Ultra-Thin Tape | ST/DTXX | PET | 3-20 | Transparent/Black | 300-1500 |

| Mesh Tape | DTXG | PET | 10-30 | Transparent | 500-1500 |

| Reflow Soldering Resistant Tape | T8X | Tissue | 50/75/100 | Translucent | 1000 |

Cushioning application/ PE foam tape

|

| Product | Series | Grade Name | Thickness(μm) | Product Color | 180° Peel Strength(gf/25mm) |

| PE Foam Tape | General Series | DP10XX | 400-1100 | Black / White | ≥1300 |

| PE Foam Tape | High Release Series | DP020XB | 100-500 | Black | ≥1600 |

| PE Foam Tape | Reworkable Series | DS39-6100B | 250 | Black | PET Surface≥1500;Foam Surface≥2000 |

| PE Foam Tape | Reworkable Series | DS396150BT | 300 | Black | PET Surface≥2000;Foam Surface≥2300 |

| PE Foam Tape | Heat-Activated Release Series | CRF-DTXXBH | 250-350 | Black | High Adhesion Surface≥ 2000;Heat-Reduced Adhesion Surface≥ 1500 |

Cushioning application/ EPT (acrylic foam tape)

|

| Product | Grade Name | Thickness(μm) | Carrier | ProductColor | 180° Peel Strength(gf/25mm) |

| EPT | A7030BR3 | 300 | Foam-type Acrylic | Black | 2500 |

| EPT | A7025B3 | 250 | Foam-type Acrylic | Black | 2200 |

| EPT | NC80XXB | 100-400 | Foam-type Acrylic | Black | 1800-3000 |

| EPT | NC90XXB | 100-400 | Foam-type Acrylic | Black | / |

Disassembly application on demand/ easy-to-disassemble tape

|

| Product | Grade Name | Single/Double Sided | Thickness(μm) | ProductColor | Carrier | Adhesion Reduction Conditions | Adhesion Release Effect |

| Easy Peel/Stretch-Release Adhesive Tape | CRN-DP Series | Double-Sided | 100-250 | White/Black | Adhesive Transfer | Stretch-Release Adhesion | / |

| Alcohol-Release Adhesive Tape | CRN-DT100CSR | Double-Sided | 100 | White | Adhesive Transfer | Alcohol-Release Adhesion | < 40 N (Suction Cup Pulling Force) |

| Electrostatic Release Adhesive Tape | EM8801-80 | Double-Sided | 80 | Silver | Conductive Composite Carrier | Electrostatic Release Adhesion | < 1 N/cm (180° Steel Plate Peel Strength) |

Disassembly application on demand: heat reducing tape

|

| Product | Grade Name | Single/Double Sided | Thickness_μm | Product Color | Carrier | Adhesion Reduction Conditions | Adhesion Release Effect N/cm (180° Steel Plate Peel Strength) |

| Heat-Release Adhesive Tape | HS5075T1-1-T | Single-Sided | 75 | Transparent | PET | 90℃, 5min | < 0.04 |

| Heat-Release Adhesive Tape | HS5115T1-3-L | Single-Sided | 115 | Blue | PET | 120℃, 5min | < 0.08 |

| Heat-Release Adhesive Tape | TR3002 | Single-Sided | 140 | Blue | PET | 135℃, 5min | < 0.12 |

| Heat-Release Adhesive Tape | CRF-DT60XXXBGSeries | Double-Sided | 150-400 | Black/Gray(Release Surface) | PE Foam | Heat-Release Adhesion | ≤ 5 |

High-strength bonding application: TSF thermosetting adhesive film

|

| Product | Grade Name | Thickness_μm | ProductColor | Pre-application Conditions | Activation Conditions | Post-activation Modulus |

| Low-Temperature Activated Thermoset Adhesive Film (PU) | CRN-DPxxxxWH | 25-300 | White / Black | 50-60℃, 0.2-0.6MPa, 2-20s | 75-120℃, 0.2-0.6MPa, 10s-180s | > 4-8 MPa(Depending on Thickness) |

| Low-Temperature Activated Thermoset Adhesive Film (PU) | CRN-DPxxxWH | 50 | White / Black | 50-60℃, 0.2-0.6MPa, 2-20s | 75-120℃, 0.2-0.6MPa, 10s-180s | > 4-8 MPa(Depending on Thickness) |

Electromagnetic shielding application: conductive tape

|

|

|

| Product | Grade Name | Single-Sided/ Double-Sided | Thickness(μm) | Product Color | 180° Peel Strength (N/25mm) | X-Y Plane Resistance (Ω/□) | Z-Axis Vertical Resistance(Ω/inch^2) |

| Conductive Plain Weave Fabric Tape | EM5/7Series | Single-Sided | 30-120 | Gray | ≥8 | <0.2 | <0.05 |

| Conductive Plain Weave Fabric Tape | EM6/8Series | Double-Sided | 30-200 | Gray | ≥10 | <0.2 | <0.05 |

| Printed Black Conductive Tape | EM5/7Series | Single-Sided | 20-50 | Matte Black / Glossy Black | ≥10 | <0.10 | <0.05 |

| Copper Foil Conductive Tape | EM5/7Series | Single-Sided | 20-50 | Metallic Color | ≥10 | <0.10 | <0.05 |

| Copper Foil Conductive Tape | EM6/8Series | Double-Sided | 30-100 | Metallic Color | ≥10 | <0.1 | <0.05 |

| Conductive Adhesive Film | EDSeries | Double-Sided | 10-100 | Gray | ≥7 | <0.1 | <0.03 |

| Conductive Nonwoven Fabric Tape | EM6/8Series | Double-Sided | 15-100 | Gray | ≥6 | <0.2 | <0.08 |

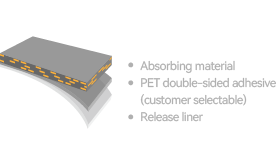

electromagnetic shielding applications: absorbing material

Absorbing material is a kind of functional material that can absorb or greatly reduce the electromagnetic wave energy projected on its surface, so as to reduce electromagnetic interference and improve the reliability of equipment. It reduces the intensity of electromagnetic waves by converting electromagnetic waves into other forms of energy such as heat energy through internal special components (such as ferrite, carbon materials, etc.).

|

| Product | Series | Grade Name | Wave Absorbing MaterialThickness(mm) | Adhesive Thickness (mm) | Operating Temperature | Magnetic Permeability (μ’@3MHz) |

| Wave Absorbing Material | Standard Type | EM91Series | 0.03/0.05/0.10/0.20/0.30/0.50 | Customizable According to Customer Requirements | -25~+85 ℃ | 50-250 |

| Wave Absorbing Material | High-Frequency Type | EM92Series | 0.10/0.20/0.30 | 0.03 | -25~+85 ℃ | 40 |

Flame retardant application/ flame retardant tape

Flame retardant application is composed of flame retardant Carrier (such as PET, PI, etc.), flame retardant and special adhesive. While retaining the performance of conventional tape, it can form a protective barrier in high temperature or open fire environment and effectively inhibit the spread of flame.

|

| Products | Model | Thickness (μm) | Single-sided/double-sided | Carrier | Color | 180 ° peel force (GF/25mm) |

| Flame retardant tape | CRI-ST050TF | 50 | Single-sided | PI | Yellow | ≥1200 |

| Flame retardant tape | CRT-DG050CF | 50 | Two-sided | PET | Transparent | ≥1500 |

Masking application: masking tape

The shading tape is composed of black pet Carrier, shading ink and special adhesive. It has both shading light and strong adhesion. It is divided into single-sided/double-sided tape. It is mainly used for fixing LCD and backlight module, shading the screen of mobile phone and preventing light leakage at the edge of electronic equipment. It also has scratch-proof and fingerprint-proof characteristics.

|

| Product | ProductGrade Name | Single-Sided/Double-Sided | Thickness(μm) | Carrier | ProductColor | 180° Peel Strength(gf/25mm) |

| Light Shielding Tape | TT32-7850B | Double-Sided | 50 | PET | Black | ≥1200 |

Other applications: AB tape

|

| Product | Series | ProductGrade Name | Thickness (μm) | Carrier | Product Color | 180° Peel Strength (gf/25mm) |

| AB Differential Tape | Standard Strong/Weak Adhesive | CRT-DGXXXD/CRT-XXXD | 50-150 | PET | Black/Transparent | 1000-3000 |

| AB Differential Tape | High Cleanliness Strong/Weak Adhesive | CRT-DTXXXD | 50-100 | PET | Black/Transparent | 1000-3000 |

Touch screen functional sheet bonding OCA

Crown New Material has launched OCA specially designed for high-end series of functional films, which is excellently suitable for precise bonding of ITO films, seamless bonding of polarizers, and stable bonding of various precision optical components. It fully meets the high standard requirements of commercial display screen and educational intelligent terminal for touch screen plug-in.

|

| Product | Grade Name | Adhesive | Thickness(μm) | Peel Strength(gf/25mm) | Refractive Index | Transmittance(T) | Haze | Yellowing Index(b*) |

| OCA for Functional Films | CR-5Series | Neutral to Slightly Hard | 100-150 | ≥2200 | 1.47-1.49 | ≥90% | ≤0.5% | ≤0.5 |

| OCA for Functional Films | CR-7Series | Moderately Soft | 50-175 | ≥2000 | 1.47-1.49 | ≥90% | ≤0.4% | 0.2 |

Glass cover plate bonding OCA

With its excellent optical performance and high adaptability, the full-fit OCA launched by Crown New Material has become a key component of high-quality display solutions in the field of consumer electronics.

|

| Product | Grade Name | Adhesive | Thickness (μm) | Peel Strength (gf/25mm) | Refractive Index | Transmittance(T) | Haze | Yellowing Index(b*) |

| Full Lamination OCA | CR-9Series | Softness | 100-250 | Pre-UV≥1000;Post-UV≥1200 | 1.47-1.49 | ≥90% | ≤0.5% | ≤0.5 |

| Full Lamination OCA | CR-9Series | Softness | 100-250 | Pre-UV≥1000;Post-UV≥1200 | 1.47-1.49 | ≥90% | ≤0.5% | ≤0.5 |

Fixing the curved screen to fit the OCA

With the continuous innovation and breakthrough of OLED technology, Crown New Material has launched a high-performance optical OCA solution for 3D curved screen display, showing excellent performance.

|

| Product | Grade Name | Adhesive | Thickness (μm) | Peel Strength (gf/25mm) | Refractive Index | Transmittance(T) | Haze | Yellowing Index(b*) |

| Curved Screen OCA | CR-9Series | Softness | 100-250 | Pre-UV≥1000 Post-UV≥1200 | 1.47-1.49 | ≥90% | ≤0.5% | ≤0.5 |

Folding screen attached to OCA

With the continuous emergence of folding screen mobile phones, Crown New Material has introduced OCA (Optical Transparent Adhesive) specially designed for folding screen, which adapts to a variety of folding needs and effectively improves the folding life of the screen.

|

| Product | Grade Name | Adhesive | Thickness (μm) | Peel Strength (gf/25mm) | Refractive Index | Transmittance(T) | Haze | Yellowing Index(b*) |

| Foldable Screen OCA | CR-7Series | Softness | 50 | ≥1000 | 1.47-1.49 | >90% | <1% | <0.5 |

Module shipment protection

|

| Product | Series | Thickness(μm) | ProductColor | Carrier | Peel-off Voltage(V) |

| PU Protective Film | Universal | 60-85 | Transparent | PET | / |

| PU Protective Film | Medium-High Adhesion | 60-85 | Transparent | PET | <500 |

| PU Protective Film | Anti-static | 60-85 | Transparent | PET | <500 |

| PU Protective Film | Low Peel-off Voltage | 60-85 | Transparent | PET | <150 |

Glass Rear Cover-Decorative Film

Product features:

|

| Product | Series | Thickness(μm) | ProductColor | Carrier | Peel-off Voltage(V) | Haze(%) | Light Transmittance(%) | Peel Strength(gf/in) |

| Decorative Film | FA8527TE | 125/188 | Transparent | PET | / | ≤1.0 | ≥90 | ≥17 |

Glass back cover: Explosion-proof film

Product features:

|

| Product | Series | Thickness(μm) | ProductColor | Carrier | Peel-off Voltage(V) | Haze(%) | Light Transmittance(%) | Peel Strength(gf/in) |

| Explosion-proof Film | / | 50/75/100 | Transparent | PET | / | ≤1.0 | ≥90 | ≥18 |

Bio-based tape

|

| Product | ProductGrade Name | Thickness(μm) | Adhesive | Carrier | ProductColor | 180° Steel Plate Peel Strength(gf/25mm) |

| Bio-based Single-Sided Ultra-Thin Tape | CRT-ST00650BMB | 5.5 | Bio-based Acrylic Adhesive | PCR-PET/Virgin PET | Black | > 250 |

| Bio-based Double-Sided Tape | CRT-DTxxxxxBB/CRT-DTxxxxxCB | 30/50/100 | Bio-based Acrylic Adhesive | PCR-PET/Virgin PET | Black/Transparent | / |

Other environmentally friendly tapes

|

| Product | Grade Name | Thickness(μm) | Carrier | Adhesive | ProductColor | 180° Steel Plate Peel Test(N/cm) |

| RCA Kraft Paper Tape | KT701 | 120 | Uncoated Kraft Paper | Hot Melt Adhesive | Brown | Summer≥ 6.25 Winter≥ 5.83 |

| RCA Kraft Paper Tape | KT702 | 130 | Uncoated Kraft Paper | Hot Melt Adhesive | Brown | Summer≥ 6.67 Winter≥ 6.25 |

| RCA Kraft Paper Tape | KT703 | 145 | Uncoated Kraft Paper | Hot Melt Adhesive | Brown | Summer≥ 7.50 Winter≥ 7.08 |

| Water-Soluble Tape | WS0908L | 85 | Water-Soluble Tissue | Water-Soluble Tissue | Light Blue | ≥ 2.5 |

Fabric/Leather and Soft Material Bonding

| TSF (Thermosetting Film) is a heat-activated adhesive film product that is non-tacky at room temperature. When activated by high-temperature heat pressing, it achieves structural or semi-structural bonding strength. It is suitable for high-strength bonding of various materials, with multiple activation temperatures available. |

| Product | Grade Name | Thickness_μm | Product Color | Pre-application Conditions | Activation Conditions | Post-activation Modulus |

| Low-Temperature Activated Thermoset Adhesive Film (PU) | CRN-DPxxxxWH | 25-300 | White / Black | 50-60℃, 0.2-0.6MPa, 2-20s | 75-120℃, 0.2-0.6MPa, 10s-180s | > 4-8 MPa(Depending on Thickness) |

| Low-Temperature Activated Thermoset Adhesive Film (PU) | CRN-DPxxxWH | 50 | White / Black | 50-60℃, 0.2-0.6MPa, 2-20s | 75-120℃, 0.2-0.6MPa, 10s-180s | > 4-8 MPa(Depending on Thickness) |

Back Cover Bonding

|

| Product | Grade Name | Thickness(μm) | Carrier | ProductColor | 180° Peel Strength(gf/25mm) |

| EPT | A7030BR3 | 300 | Foam-type Acrylic | Black | 2500 |

| EPT | A7025B3 | 250 | Foam-type Acrylic | Black | 2200 |

| EPT | NC80XXB | 100-400 | Foam-type Acrylic | Black | 1800-3000 |

| EPT | NC90XXB | 100-400 | Foam-type Acrylic | Black | / |

Camera Module Bonding

ChatGPT 说: |

| Product | Adhesive Transfer Tape | Adhesive Transfer Tape | PET Tape | PET Tape | PET Tape | PET Tape | PET Tape | PET Tape |

| Series | High-Performance Series | General Series | High-Performance Series | High-Performance Series | High-Performance Series | High-Performance Series | General Series | Dry Die-Cutting |

| Grade Name | N5X | NCX | P89X2G | P89xxLE/A | P89X21G | P89X22G | 79X | 69XLE |

| Thickness(μm) | 60/130 | 50/130 | 50-100 | 100-200 | 50-100 | 50-100 | 30-245 | 30-100 |

| Carrier | / | / | PET | PET | PET | PET | PET | PET |

| ProductColor | Transparent | Transparent | Transparent | Transparent | Transparent | Transparent | Transparent/Black | Transparent/Black |

| 180° Peel Strength(gf/25mm) | 2500/3000 | 1000-1500 | 1500-2400 | 1500-2000 | 1500-2400 | 1800-3000 | 600-3000 | 600-1200 |

Component Grounding / EMI Shielding Applications

Conductive Woven Fabric Tape:High conductivity, excellent flex resistance, and superior tear resistance. Conductive Non-Woven Fabric Tape: High conductivity, good conformability, and clean die-cutting with minimal fraying. | Black-Printed Conductive Tape: Enhanced light-blocking for improved appearance; available with conductive fabric or copper foil options. Copper Foil Conductive Tape: Low electrical resistance, excellent electromagnetic shielding, and strong adhesion. |

ChatGPT 说: |

| Product | Grade Name | Single-Sided/Double-Sided | Thickness(μm) | Product Color | 180° Peel Strength(N/25mm) | X-Y Plane Resistance (Ω/□) | Z-Axis Vertical Resistance(Ω/inch^2) |

| Conductive Plain Weave Fabric Tape | EM5/7Series | Single-Sided | 30-120 | Gray | ≥8 | <0.2 | <0.05 |

| Conductive Plain Weave Fabric Tape | EM6/8Series | Double-Sided | 30-200 | Gray | ≥10 | <0.2 | <0.05 |

| Printed Black Conductive Tape | EM5/7Series | Single-Sided | 20-50 | Matte Black / Glossy Black | ≥10 | <0.10 | <0.05 |

| Copper Foil Conductive Tape | EM5/7Series | Single-Sided | 20-50 | Metallic Color | ≥10 | <0.10 | <0.05 |

| Copper Foil Conductive Tape | EM6/8Series | Double-Sided | 30-100 | Metallic Color | ≥10 | <0.1 | <0.05 |

| Conductive Adhesive Film | EDSeries | Double-Sided | 10-100 | Gray | ≥7 | <0.1 | <0.03 |

| Conductive Nonwoven Fabric Tape | EM6/8Series | Double-Sided | 15-100 | Gray | ≥6 | <0.2 | <0.08 |

Structural Component Bonding

|

| Product | Series | Grade Name | Thickness(μm) | Carrier | Product Color | 180° Peel Strength(gf/25mm) |

| Adhesive Transfer Tape | High-Performance Series | N5X | 60/130 | / | Transparent | 2500/3000 |

| Adhesive Transfer Tape | General Series | NCX | 50/130 | / | Transparent | 1000-1500 |

| PET Tape | High-Performance Series | P89X2G | 50-100 | PET | Transparent | 1500-2400 |

| PET Tape | High-Performance Series | P89xxLE/A | 100-200 | PET | Transparent | 1500-2000 |

| PET Tape | High-Performance Series | P89X21G | 50-100 | PET | Transparent | 1500-2400 |

| PET Tape | High-Performance Series | P89X22G | 50-100 | PET | Transparent | 1800-3000 |

| PET Tape | General Series | 79X | 30-245 | PET | Transparent/Black | 600-3000 |

| PET Tape | Dry Die-Cutting | 69XLE | 30-100 | PET | Transparent/Black | 600-1200 |

Battery Fixation

ChatGPT 说: | Alcohol-Release Adhesive Tape: Adhesion is reduced quickly and efficiently by alcohol application. Heat-Release Adhesive Tape: High initial tack before release; offers effective adhesion reduction when heated.

|

| Product | Grade Name | Single/Double Sided | Thickness(μm) | Color | Carrier | Adhesion Reduction Conditions | Adhesion Release Effect |

| Easy Peel/Stretch-Release Adhesive Tape | CRN-DPSeries | Double-Sided | 100-250 | White/Black | Adhesive Transfer | Stretch-Release Adhesion | / |

| Alcohol-Release Adhesive Tape | CRN-DT100CSR | Double-Sided | 100 | White | Adhesive Transfer | Alcohol Soluble Adhesive Removal | < 40 N (Suction Cup Pulling Force) |

| Electrostatic Release Adhesive Tape | EM8801-80 | Double-Sided | 80 | Silver | Conductive Composite Carrier | Electrostatic De-adhesion | < 1 N/cm (180° Steel Plate Peel Strength) |

Graphite Sheet Bonding

|

| Product | Grade Name | Carrier | Thickness(μm) | Color | 180° Peel Strength(gf/25mm) |

| Ultra-Thin Tape | ST/DTXX | PET | 3-20 | Transparent/Black | 300-1500 |

WPC Bonding

|

| Product | Series | Grade Name | Wave Absorbing MaterialThickness(mm) | Adhesive Thickness (mm) | Operating Temperature | Magnetic Permeability (μ’@3MHz) |

| Wave Absorbing Material | General | EM91Series | 0.03/0.05/0.10/0.20/0.30/0.50 | Customizable According to Customer Requirements | -25~+85 ℃ | 50-250 |

| Wave Absorbing Material | High-Frequency Type | EM92Series | 0.10/0.20/0.30 | 0.03 | -25~+85 ℃ | 40 |

Smartphone Frame Bonding and Fixation

|

| Product | Grade Name | Thickness(μm) | Carrier | Color | 180° Peel Strength(gf/25mm) |

| EPT | A7030BR3 | 300 | Foam-type Acrylic | Black | 2500 |

| EPT | A7025B3 | 250 | Foam-type Acrylic | Black | 2200 |

| EPT | NC80XXB | 100-400 | Foam-type Acrylic | Black | 1800-3000 |

| EPT | NC90XXB | 100-400 | Foam-type Acrylic | Black | / |

Cover Glass and Display Module Lamination

|

| Product | Grade Name | Adhesive | Thickness(μm) | Peel Strength(gf/25mm) | Refractive Index | Transmittance(T) | Haze | Yellowing Index(b*) |

| Full Lamination OCA | CR-9Series | Softness | 100-250 | Pre-UV≥1000;Post-UV≥1200 | 1.47-1.49 | ≥90% | ≤0.5% | ≤0.5 |

| Full Lamination OCA | CR-9Series | Softness | 100-250 | Pre-UV≥1000;Post-UV≥1200 | 1.47-1.49 | ≥90% | ≤0.5% | ≤0.5 |

Flexible Circuit Grounding

Conductive Woven Fabric Tape: High conductivity, excellent flex resistance, and improved tear resistance. Conductive Non-Woven Fabric Tape: High conductivity, good conformability, and clean die-cutting with minimal fraying. Conductive Adhesive Film: Excellent bonding performance. | Black-Printed Conductive Tape: Enhanced shielding capability and improved appearance, available with conductive fabric or copper foil options. Copper Foil Conductive Tape: Low electrical resistance, excellent electromagnetic shielding, and strong adhesion.

|

| Product | Grade Name | Single-Sided/Double-Sided | Thickness(μm) | Color | 180° Peel Strength(N/25mm) | X-Y Plane Resistance(Ω/□) | Z-Axis Vertical Resistance(Ω/inch^2) |

| Conductive Plain Weave Fabric Tape | EM5/7Series | Single-Sided | 30-120 | Gray | ≥8 | <0.2 | <0.05 |

| Conductive Plain Weave Fabric Tape | EM6/8Series | Double-Sided | 30-200 | Gray | ≥10 | <0.2 | <0.05 |

| Printed Black Conductive Tape | EM5/7Series | Single-Sided | 20-50 | Matte Black / Glossy Black | ≥10 | <0.10 | <0.05 |

| Copper Foil Conductive Tape | EM5/7Series | Single-Sided | 20-50 | Metallic Color | ≥10 | <0.10 | <0.05 |

| Copper Foil Conductive Tape | EM6/8Series | Double-Sided | 30-100 | Metallic Color | ≥10 | <0.1 | <0.05 |

| Conductive Adhesive Film | EDSeries | Double-Sided | 10-100 | Gray | ≥7 | <0.1 | <0.03 |

| Conductive Nonwoven Fabric Tape | EM6/8Series | Double-Sided | 15-100 | Gray | ≥6 | <0.2 | <0.08 |

Electromagnetic Shielding (EMI Shielding)